Well, the X-Ray was inconclusive. Let’s get a CT scan for a better look. Last week we detailed Diagnostic Radiographer Brandon Bertolli’s analysis of his A-TEC CMM6 rimfire suppressor. He has since followed up with part two that includes additional observations of shooting 6000 rounds of .22lr through a suppressor without any maintenance.

On the surface, these results seem obvious: If you shoot a rimfire can without a cleaning schedule, you are going to have residue build up. However, using an X-Ray and a CT scanner to identify the location deposits is a unique insight into the life of a rimfire silencer. Bertolli should be commended for his dedication to the scientific process – my OCD wouldn’t let my rimfire suppressors go 500 rounds without a solid cleaning.

Never heard of an A-TEC CMM6? They are manufactured in Norway. Meaning that with the restrictions applied to the importation of silencers, most Americans have never had the pleasure of owning, let alone shooting an A-TEC product.

The next time I am in Norway, I’m definitely dropping in for a visit.

End cap observations:

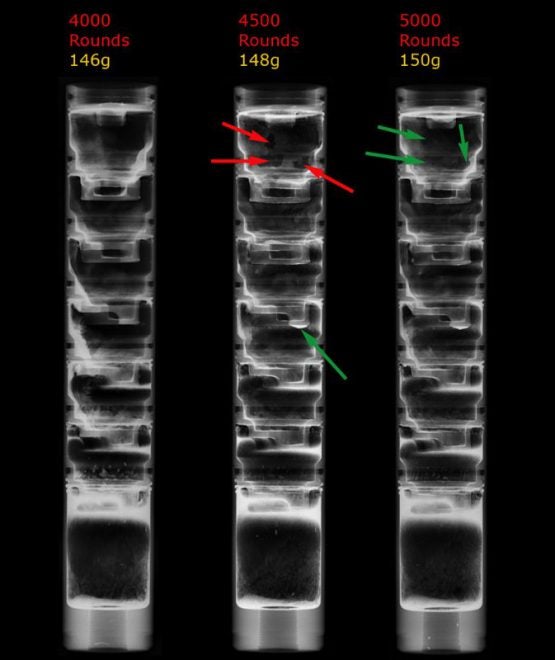

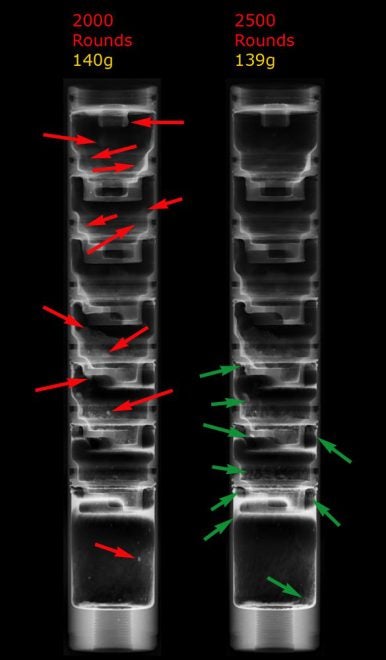

Despite the loss of lead from 4000 to 4500 rounds, the suppressor picked up weight. At 4500 rounds a new large lead deposit can be seen attached to the underside of baffle number 4 (arrowed in the radiograph above, at 4500 rounds). There is also more new lead in the corner adjacent to that new deposit.

If the radiographs are inspected carefully, you can find areas of lost lead and new lead throughout the sequence.

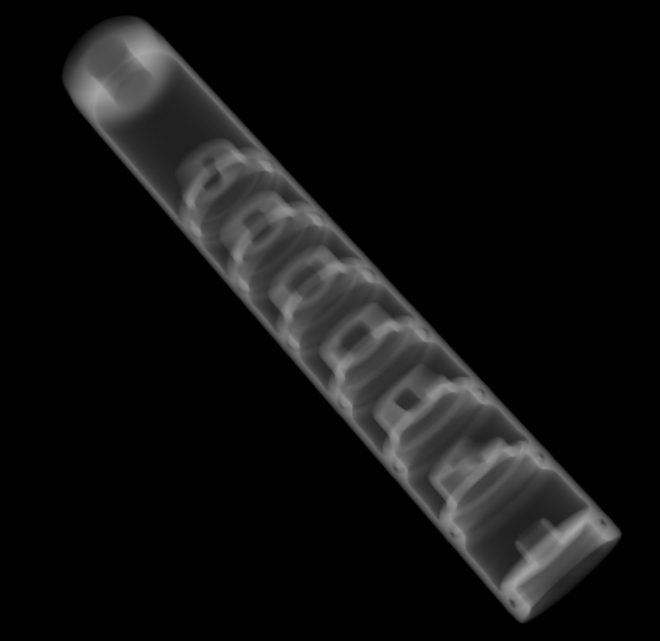

There is a design variable to be aware of, which is that the baffles on this A-TEC CMM4(6) are arranged in a spiral pattern. This means that the baffles are rotated relative to the ones underneath. There are also very small differences in the centring point of the X-ray beam and the orientation of the suppressor relative to the detector. I use the manufacturer’s mark to align the surface of the suppressor with the axis of the central ray of the X-ray beam.

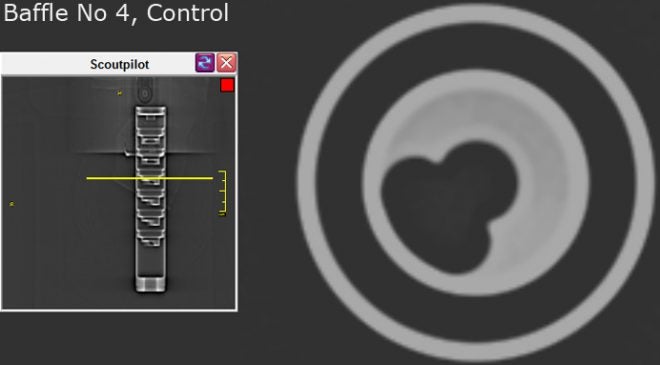

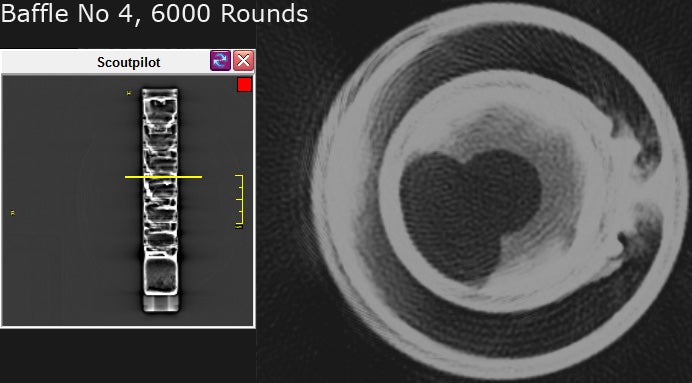

My colleagues have kindly provided me with CT scans of this suppressor before it was used (control) and also at the 6000 round mark. Below are two axial images from those scans, at the shoulder of baffle number 4:

Note the reconstruction artefacts on the CT from the 6000 round mark, caused by the dense lead deposits inside the suppressor. Nonetheless the lead is detectable and the asymmetric pattern of deposition can be appreciated.

The spiral arrangement of the baffles can be appreciated in this 3D reconstruction of the axial CT images (which I created using Sectra™ IDS7 PACS):

1) Although there are weight and lead deposition fluctuations, the overall trend is for this suppressor to pick up weight (if it is not cleaned or sprayed in any way). The weight gain is 23.7g so far, at 6000 rounds.

2) I have not noticed any problems with accuracy or sound suppression at the 6000 round mark, although I concede I have not tested this scientifically.

3) Obviously the weight of this suppressor cannot go up indefinitely. I would like to find out what the end weight is. To speed things up I will not fire any more CCI Mini-mag through this suppressor. I will be using Eley Sport or RWS Target Rifle ammunition from this point on.

There are several improvements I intend to make, concerning potential tests of other suppressors. I welcome any comments…

bbertolli(at)yahoo(dot)com

Your Privacy Choices

Your Privacy Choices