Note: In this article, I call this mechanical feature “underlug”. However, this is an error. Several friends of mine and I have been discussing the mechanics of firearms operation for close to a decade now, and we misremembered the term “underslide” from a book by Brassey’s as “underlug”. More details on the error are available in the comments. Regardless, “underslide” is the proper term for this principle, not “underlug”.

When a firearm unlocks, even if the bullet has already left the barrel, some residual pressure remains in the chamber, forcing the cartridge case walls out against the chamber, and causing resistance against the extraction of the spent case from the barrel. Within a single instant, the pressure in the barrel is relieved and the case walls rebound elastically away from the chamber. In a manually operated gun, the reaction of even the quickest shooter is too slow to operate the gun before the pressure in the barrel can drop, so this residual pressure does not present a problem. However, in automatic weapon design the weapon’s mechanism virtually by necessity must begin to operate while pressure in the chamber is still high, and this presents the problem of how to provide energy to the mechanism while there is ample pressure to do so, yet still extract the cartridge case when the pressure drops to a low enough level to allow the case to easily leave the chamber without risk of shearing a rim, or worse.

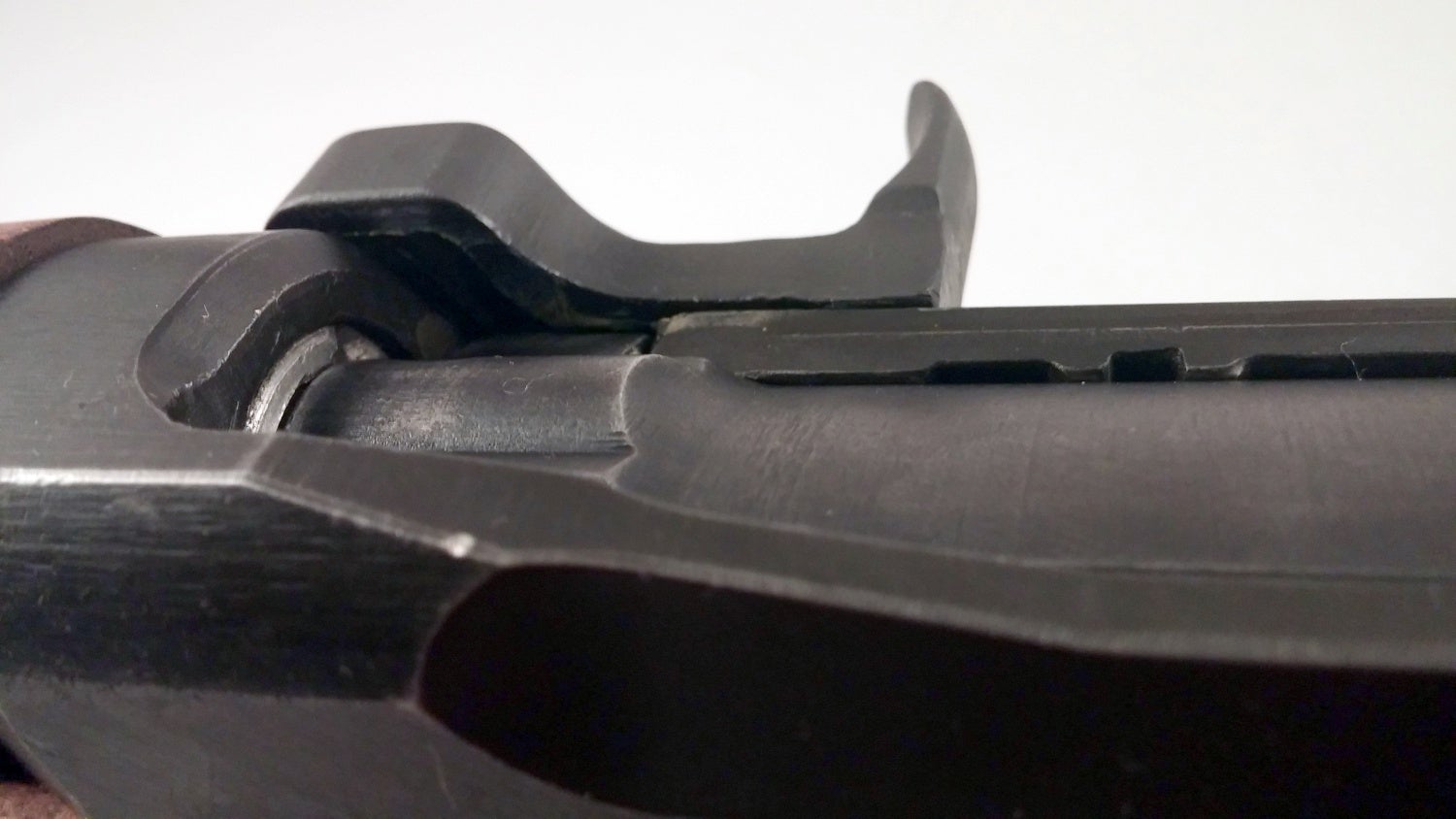

There are several inventions which solve this problem, including the expanding gas system of the AR-15 and John Pedersen’s cartridge waxing process, but one of the most mechanically sound ways is called underlug. Underlug is a special dimensioning of the cam surfaces on a locked-breech firearm which give the actuating piece space to move before it actually contacts the locking element and unlocks the firearm. As an example, below we can see the underlug on the cam track of an M1 rifle’s operating rod and how it interacts with the unlocking stud on the bolt lug, at the timestamp 5:29 in the U.S. Army video below:

You can see from 5:29 – 5:36 how the operating rod is able to move to the rearward significantly (in reality, roughly 3/8ths of an inch/9mm, although significantly exaggerated in the illustration above) before it encounters the locking stud and forces the bolt open. This delay in unlocking not only gives the operating rod a running start to unlock the rifle, it also allows pressure to drop in the chamber before the extractor is forced to pull the case out, easing extraction.

In the locked position, the bolt is rotated into position and the operating rod is fully forward:

The operating rod is able to move back slightly (~3/8″), but the bolt stays in the locked position and does not yet start to rotate:

Now the bolt has rotated out of alignment with the locking surfaces in the receiver:

Your Privacy Choices

Your Privacy Choices