When we broke the latest installment of the SureFire vs Operators Suppressor Systems (OSS) saga last Thursday, I expressed my devotion to both data and facts over unreliable emotions. Within hours, the comments section, internet forums and my inbox were flooded with unsupported claims ranging from license revocations to an end of business operations within a few months. And after speaking with multiple parties intimate with the situation, none of the allegations seemed to be rooted in fact. That is, until last night.

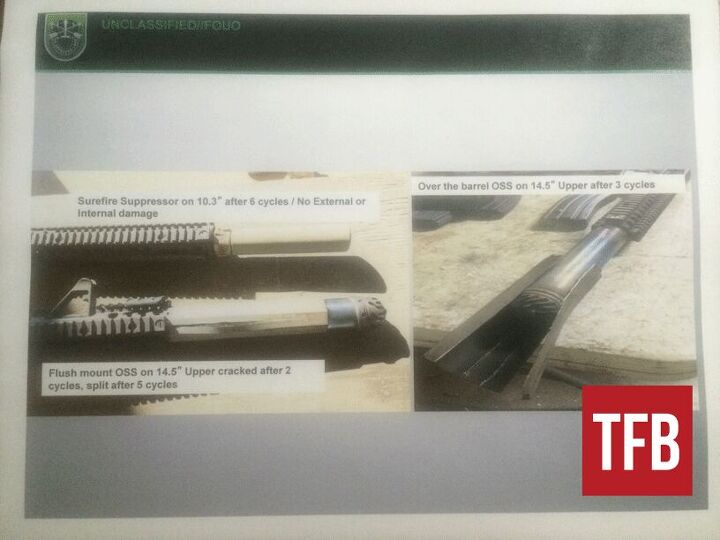

An anonymous source provided TFB with the following images allegedly depicting OSS Suppressor(s) failing DOD testing. This source reports receiving the images from an unidentified third-party. Although the images were labeled ‘unclassified’, out of an abundance of caution, certain test specifics, some DOD identifying information and individual personal identifiers were redacted – the last thing we want to do is put our Warfighters at any additional risk.

Important note: The authenticity, date/time or origination of the images have not yet been verified. So, even though they look official, the images cannot be be taken solely on face value. Although, OSS does acknowledge one of the pictures below as being a part of prior tests.

I sent a selection of the below images to both SureFire and OSS for official comment. Their responses are below.

SureFire:

We cannot comment on government testing that we had absolutely no involvement with.

OSS:

As we said in our release the other day…

Last fall, in OSS’s ongoing collaboration with the US Government and Military, prototype OSS suppressors were tested and experienced a handful of heat-related fails to outer housings and internal components.

This picture was one of our prototype flush mount suppressor — and as you can see, the outer housing in this early design didn’t pass this test protocol.

As part of ongoing government and OSS testing like this, metal and geometry modifications were made, virtually identical testing was repeated in January, and our latest design not only withstood the brutal firing table, but delivered the levels of sound and flash suppression and weapon performance far beyond the level required by the test.

As determined by the US Government agency that conducted the January test, the best-in-class baffle suppressor did not.

OSS’s patented Flow-Through™ suppression technology is a disruptive leap ahead of 110 year old baffle suppression technology. Around the world, OEM weapon system manufacturers, military and Special Forces, and others are rapidly recognizing the inherent limitations of baffle suppression. At OSS we fully embrace an honest and open evaluation of our products, and look forward to future reporting by this and other blogs.

One over the barrel and one flush-mount suppressor were tested:

I doubt this will be the final word in the OSS versus SureFire durability testing debate. However, I think it should be. OSS should submit a few suppressors to an independent testing lab for verifiable durability testing. I’m not even sure why they decided to test a SureFire silencer in a head-to-head comparison alongside their product. Let your own tests results stand alone.

I’m not saying OSS should have released the above information, however prudence would dictate caution when calling out your competitor if your product had dramatically failed a similar test in the past.

#nodrama

Your Privacy Choices

Your Privacy Choices