Previously in our introductory series on ballistics, we’ve discussed the concept of caliber, as well as ballistic coefficient and its close relative form factor. Today, we’re going to look at the concept of rifling, and how it relates to bullet stability.

First, though, we’ll need to define a term:

- Bore: The hole drilled in the barrel of a firearm, through which the bullet travels when it is fired.

The earliest firearms had simple tubular bores, like a modern shotgun. In the late 1400s, gunsmiths in what is now Germany developed a method of scraping grooves in barrels to allow room for blackpowder and lead fouling to build up, hopefully prolonging the accuracy of the barrels before they needed to be cleaned. They found, eventually, that by twisting these grooves in a barrel, they could dramatically improve its accuracy. These grooves became known together as “rifling” and they are a key technology in modern rifle (as the name suggests) and pistol barrels.

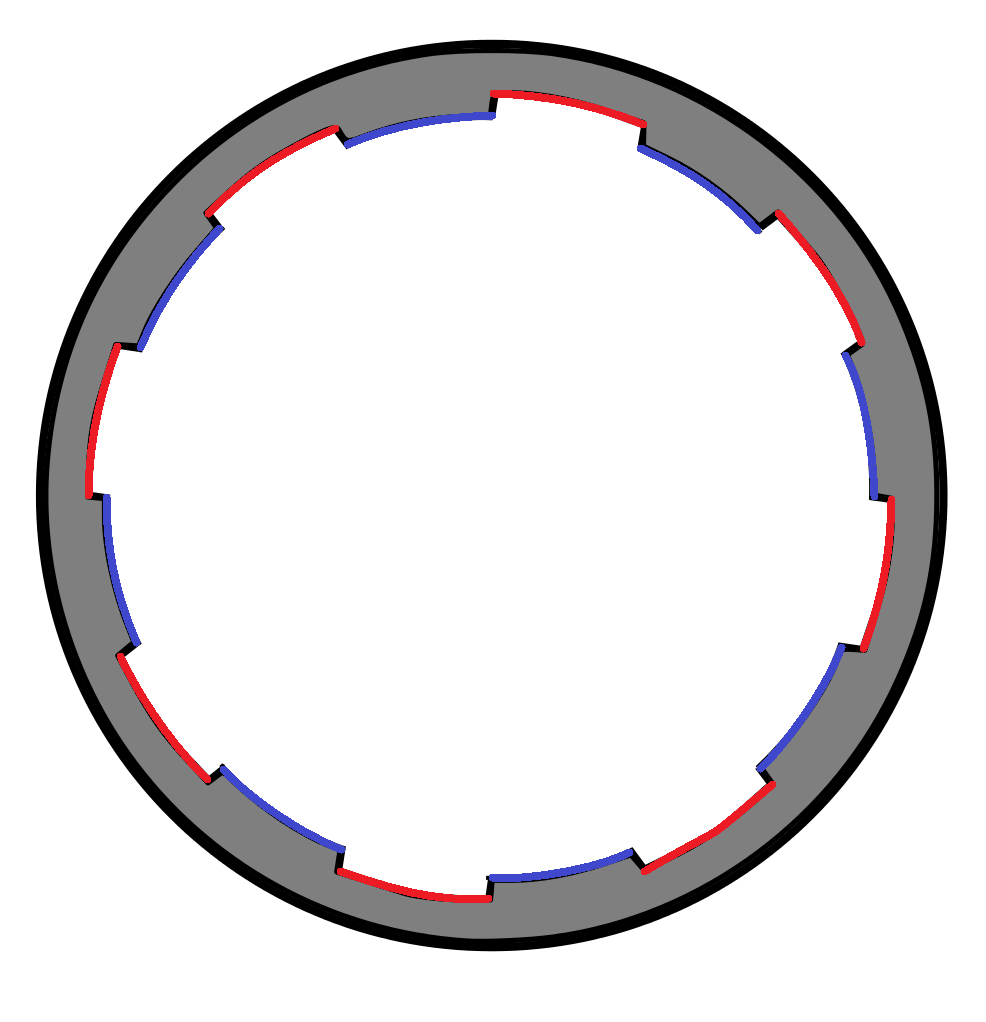

A cross-section of 8-groove rifling. The red highlighted segments are “grooves” and the distance between opposite grooves is called the “groove diameter”. The blue highlighted segments are called “lands”, and the diameter between opposite lands is called “bore diameter”.

Rifling works by spinning the projectile about its axis, causing gyroscopic forces that spin-stabilize it throughout its flight; tighter rifling will spin a bullet faster, while looser rifling will spin a bullet slower. The rate at which the bullet is spun is very closely tied to how stable it will be; too slow, and the bullet will tumble in the air, too fast and the bullet may break apart in flight. The speed of rotation caused by rifling is determined by the rifling’s pitch or twist rate, which describes how loose or tight the rifling is twisted inside the barrel. Usually, rifling twist in the United States is described by a phrase like one turn in N inches, often shortened to “1:N” or “1/N”, which refers to the distance over which the bullet would complete one full revolution.

For example, the US Army’s M4 Carbine has a twist rate of one turn in 7 inches (“1:7” or “1/7”), which is quite tight. An M4 Carbine with a fairly new barrel firing 5.56mm M855 ammunition will spin the projectile at over 5,000 rotations per second to stabilize its flight!

Your Privacy Choices

Your Privacy Choices