In this 201-level post on the devices and mechanisms that automatic firearms use to do their work, we’ll be discussing a distinction between two very similar types of gas systems. These are what’s commonly known as the “Ljungmann-type” gas system (called so after a Swede, even though in reality a Frenchman invented it decades earlier) and “Stoner-type” gas system. Both are forms of what’s called “direct impingement”, a term which has two different meanings, one of which we’ll discuss today

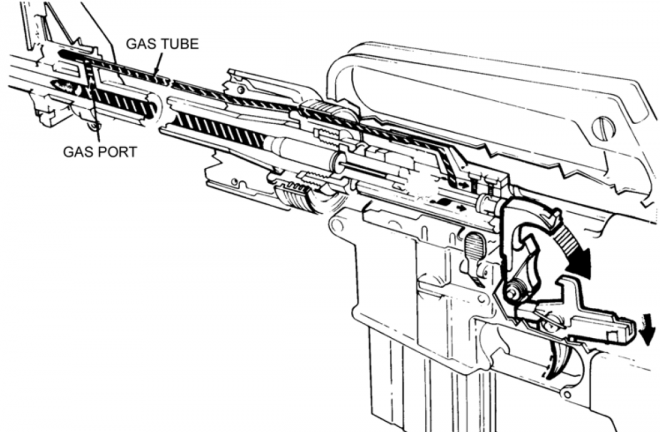

- Direct gas impingement (often just “DI”): Commonly refers to a gas system whereby propellant gases are bled through a long tube reaching from a gas port, mounted somewhere on the barrel body, all the way back to the breech to meet the moving parts group.

The other use is more broad and only appears in US Army technical documents, so we’ll ignore it for now. Since both Stoner-type and Ljungmann-type gas systems are direct impingement, that means they both use a long gas tube and both bring gas rearward either up to or beyond the uprange end of the barrel. However, there the similarities end. Ljungmann-style DI simply directs the gas from the tube directly against an impinging surface on the moving parts group. Stoner DI is more complicated, as it routes the gas from the tube to a channel in a bolt carrier, where the gas is then allowed to expand between the bolt and bolt carrier. YouTuber Bloke on the Range explains below exactly how that works, what the difference is between the two systems, and what advantages the Stoner system enjoys:

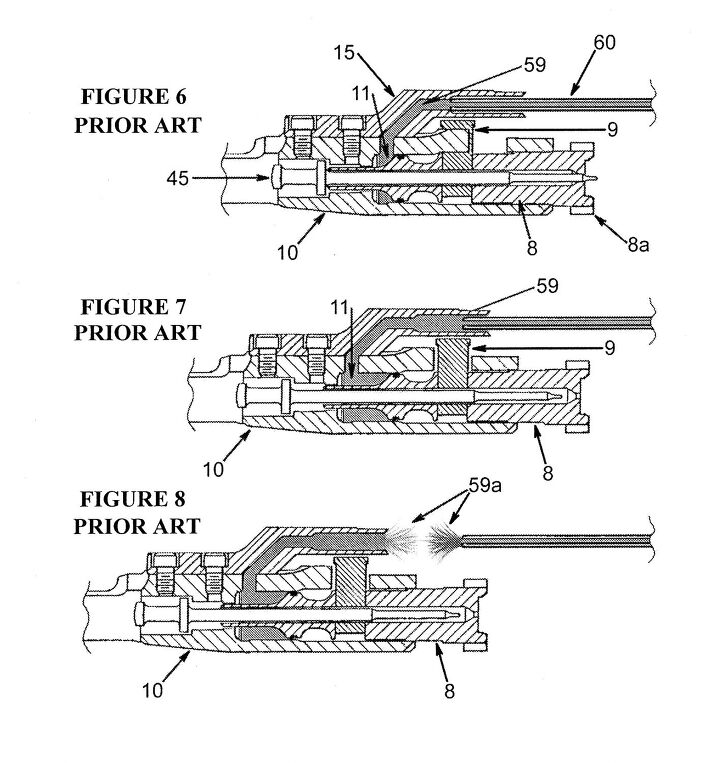

For those who do not want to watch the video, you can see a clear image of this process in an image from Richard Crommet’s patent on the ICE-15 carbine:

You can see how the gas (59) is tapped through the tube (60) into an extension of the bolt carrier (10) called the “carrier key” (15), where it expands inside a toroidal chamber (11) created by the space between the bolt (8) and the bolt carrier. This unlocks the bolt and forces the moving parts group as a whole to the rear.

As Bloke noted above, the Stoner-type system enjoys the advantages of very even forces on the moving parts group, forces that are almost totally in-line with the bore itself. This almost eliminates stress on the rifle’s receiver, which allows the designs like the AR-15 that use Stoner’s system to have very lightweight receivers with no strengthened receiver rails. In contrast, the Ljungmann-type system creates off-axis forces that require tough receiver rails, which increases the weight of the weapon’s receiver.

Your Privacy Choices

Your Privacy Choices