As most readers know, my chosen shooting platform is the Glock, Generation 4. Despite its continued commercial success, I swear that it still remains the step-child of the aftermarket, as nearly everyone only offers various components for the Generation 3 editions including slides, springs, etc.

Finally, the 4th Generation is starting to get the attention it deserves. With the better recoil spring system and better factory grip texture, adjustable straps, its simply the the better gun for the aftermarket where the increased room and various interfaces allow one to more flexibility for innovative products.

Taking advantage of this increased room is Advance Dynamic Systems (hereafter “AD”) of California. AD has released their RMS stainless steel guide rod, which uses the room to create a heavier “reverse plug” for the competition Glock 34 and 35 models while maintaining a flat spring common to the Generation 3 handguns.

The RMS, as described by Advance Dynamic:

The Advance Dynamic RMS stainless steel guide rod and heavy-weight reverse plug are solid upgrades that improve the performance and reliability of your Gen4 Glock by converting the recoil spring configuration to the proven design found in Gen3 Glocks.

The RMS guide rod and heavy-weight reverse plug are CNC machined from 416 Stainless Steel bar stock for extended service life and is paired with an ISMI chrome silicon recoil spring. Our design uses the optimal spring tension for Gen4 Glocks to ensure proper cycling even with a weapon light attached. The RMS steel guide rod combined with the weight of the reverse plug reduce felt recoil to allow for fast follow up shots and allow you to use a wider variety of ammunition when compared to a factory Gen4 Glock models

I personally take a bit of issue with the statements “such as wider variety of ammunition” as this has been untrue in my experience, but the gist of the product is there. Its basically a weight that plugs the front of the competition models, a stainless guide rod, and a flat wire spring. Its a simple arrangement, but does it work as well in practice as it does in theory?

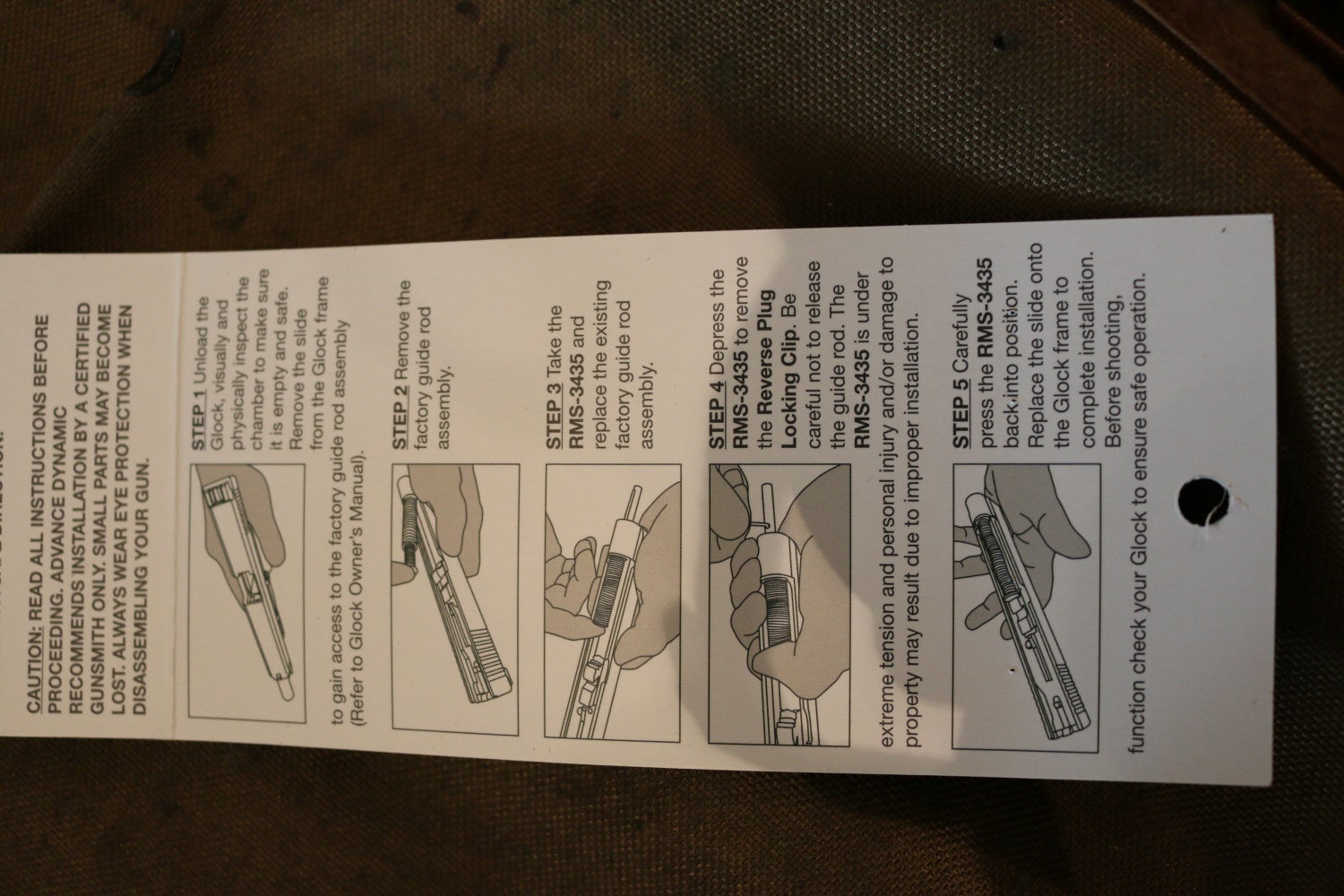

Installing the RMS

Author’s note: The test platform was a Glock Gen 4 G35 .40 S&W tested in both .40 and 9mm using a Lone Wolf 40-9mm conversion barrel. I typically shoot the G35 as 9mm in competition. Shooting experience was compared to the standard Glock recoil assembly and a Lone-Wolf polished recoil assembly.

As noted in the picture above, the RMS arrives as an assembly, held in place by a cotter pin. The pin inserts about 1/3 the way up the rod, held in place by the tension of the spring acting on the plug. The pin is very necessary, as the assembly is not “captured” or held together as a unit. With the strength of the spring in compression, it would otherwise be very difficult to insert the assembly into a handgun.

Things brings up my only real complain on the RMS system, why is the assembly not captured up front? Adding a threaded hole and a matching stainless button-head screw up front would cost cents and greatly increase the ease of installation and removal of the system. I understand that the overall shooting experience was the primary goal, but find this omission incredibly annoying as to test the RMS in all the calibers, I installed and removed it dozens of times and if one loses the pin, the difficulty increases exponentially. (In one instance, the plug shot over 100 feet down-range for me).

Once the plug is in the slide, remove the pin and carefully guide the rod back into the barrel’s interface. Once set, the plug keeps the guide rod straight and the completed slide assembly can be installed normally onto the frame. Testing the action, the slide racked smoothly and dry-fire testing indicated that the handgun was ready for service.

Experiencing the RMS

Prior to shooting the handgun, I did a few “feel” test of the RMS versus other recoil spring assemblies. With a second identical handgun (I always have duplicates of all my competition rigs), the RMS was compared with a standard Glock and polished Lone Wolf recoil spring assembly.

In terms of “smoothness” the RMS and Lone Wolf were directly on part with one another. The Glock recoil system always has a harsh, but function feeling (the same could be said of Glocks, period). What was noticed was a slightly louder sound of the plug rubbing over the guide rod. While this has absolutely no bearing on shooting, it was noticed on the bench.

Lining up the handgun down-range, I did not notice the extra weight up front while dry-firing. Simply put, its so little extra relative to the overall weight of the system, only a keen shooter could notice. However, moving into live fire, the plug makes its presence known.

Its not a full-on “night and day” shooting difference, but it could be described as “twilight vs dusk”. The key is the physics involved. The added weight to the cycling mass on a handgun will slow down the slide (assuming spring rates are the same). By slowing it down, the recoil impluse is spread over a slightly longer period of time. From there, adding weight to the front of the handgun will then impart more force to drive the nose of the handgun down as the slide goes into battery.

As such, the RMS doesn’t change the overall recoil (as energy is the same, just delivered over a longer period), it does reduce the “felt” recoil as shoves are easier to handle than jerks and with the weight added, drives the muzzle down.

For a shooter like myself where I am used to a handgun and have long compensated to the recoil impulse, it actually drove the muzzle down too far for me during the first magazine, creating some fun vertical strings on the target, but after a few magazines, I was able to compensate and targets shrunk to my standard sizing quickly.

My split times however did not decrease markedly. With either the RMS or my standard rig with the Lone Wolf polished system, I was holding to normal splits and accuracy. However, the RMS was at a bit of a disadvantage, as the Lone Wolf spring system is tuned to my load, so the RMS keeping pace with its standard spring is impressive. This is backed up with the nose of the handgun “diving” where a lighter spring would have pushed it down less.

Moving between calibers, the effect was much more noticeable with the .40 ammunition. With its common “snap”, the added mass was a nice addition, especially when moving up to defensive loads like Federal HST. On 9mm (Freedom 124 grain re-manufactured) the effect was there, just no as pronounced.

Author’s note: AD did not yet have their other springs available at time of testing. They have since introduced various spring rates for shooters to tune the system.

The Good:

- In today’s market of over-hyped product, having sometime do exactly as it purports to do is refreshing.

- Does reduce “felt” recoil and helps drive down the muzzle during firing.

- Various spring rates available for the shooter to tune the system to their experience.

The Notable:

- With in being stainless, I would like to see this nitrocarburized or “nitrided”. Adding the black will match the handgun and will increase surface hardness while reducing friction further.

- Should be compatible with nearly any Generation 3 spring set if the desired spring is not offered by AD.

- I’d be curious to see the results of offering a tungsten carbide increasing weight further up front, but that is only curiousity speaking.

The Bad

- This should be a captured system.

Final Thoughts:

The AD RMS is a solid offering. It does exactly what it sets out to do, which is to reduce the felt recoil of the shooter. Its an innovative approach that takes advantage of the Glock Gen 4’s added space to create a product caters to a specific shooter.

While I am annoyed at the choice to not capture the system, the RMS will make shooting the Glock 34 and 35 more pleasant. Adding in the compatibility with various springs and AD’s new spring rates, the competitive shooter can expect a performance boost dropping it in.

Your Privacy Choices

Your Privacy Choices