Over the past several months we’ve been fortunate enough to tour all of Remington’s major facilities for gun manufacturing and ending with this tour of the ammunition plant located in Lonoke, Ar. All of Remington’s ammunition is made at this plant.

The entire compound which includes the original plant, the new extension plant as well as the Remington Gun Club covers some 1200 acres of Arkansas forest and wetlands. In fact the area within the fenced acreage has enough deer and other game for the company employees to hunt.

When the facility was constructed in 1969, and opened in 1970, it was so far removed from any city or services they actually had to construct it to be self sustaining. They even have their own hospital inside the plant which is still in operation today.

The white pipes in the photo are part of the 14 miles of steam lines. These two photos taken from the top of the shot tower.

Today there are 1257 employees with 1124 of them full time. The facility is located 20 miles from Little Rock, Ar. off I-40. The plant has 750,000 square feet under roof with the new building extension adding another 74,000 square feet. There are a total of 46 total structures on the property.

Generally they run 3 shifts 5 days per week with 4 shifts 7 days a week 24/7 in some areas. The annual production is 2.6 billion rounds of ammunition and 100 million component products. Nearly 1300 pieces of equipment are used in this high volume facility. The plant also uses 44 million lbs. of lead per year and 12 million pounds of copper per year! Amazingly the entire operation uses 400,000 gallons of water per day! As you travel around the area you’ll notice a large number of steam lines. These lines total 14 miles in length.

Let’s move inside the main plant now and have a look at the raw materials, machinery and various stages of constructing rifle, handgun and shotgun ammunition.

In this set of photos we’ll see the raw lead as it’s received at the plant and then turned into rolls.

After these rolls are placed into another piece of equipment they are spun into uniform diameter loops which will then be cut to length as the lead core for rounds being made or as wadcutters.

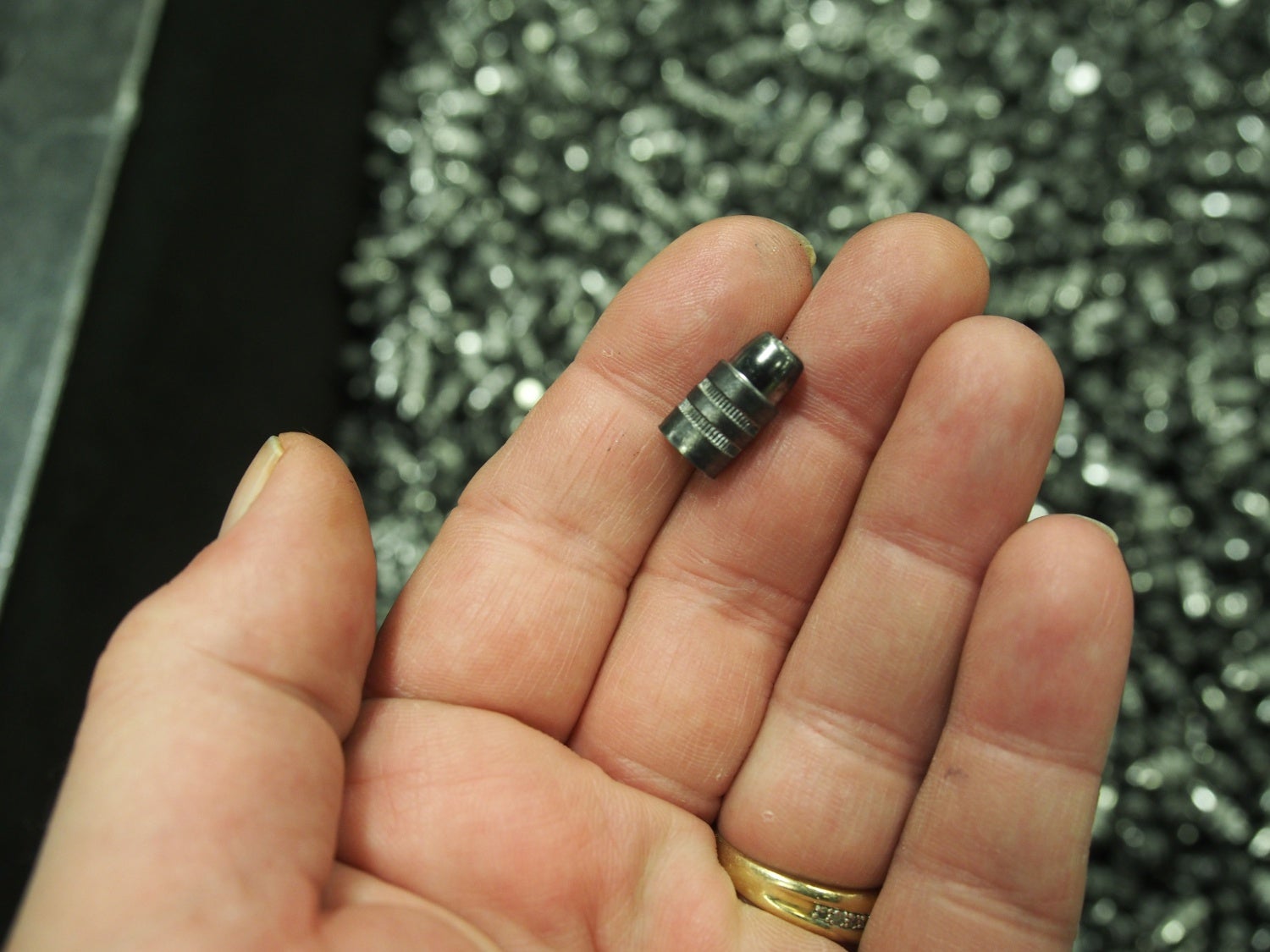

Individual loops of well— bullets waiting to be cut as they are fed into another machine depending on whether it’s a wadcutter or bullet core.

Here is the lead after it comes out of the next process and dumped into large containers.

Part 2 will cover the use of brass in making rifle and handgun jackets for various caliber bullets. On this day they will be making 45 acp bullets, British .303 and .380 bullets. I’ll also cover the entire process as the components come together to complete a full loaded round of ammo. Look for part 2 the first of the coming week.

Your Privacy Choices

Your Privacy Choices