Several months ago, Tom R and I were approached by Clark Armory to conduct ballistic tests of several popular self-defense rounds. For testing, we were provided two of Clear Ballistics, 10% Ballistic Gelatin F.B.I Blocks.

Key features of the 10% Ballistic Gelatin FBI Block include:

- The FBI block is 100% Synthetic and contains no organic material.

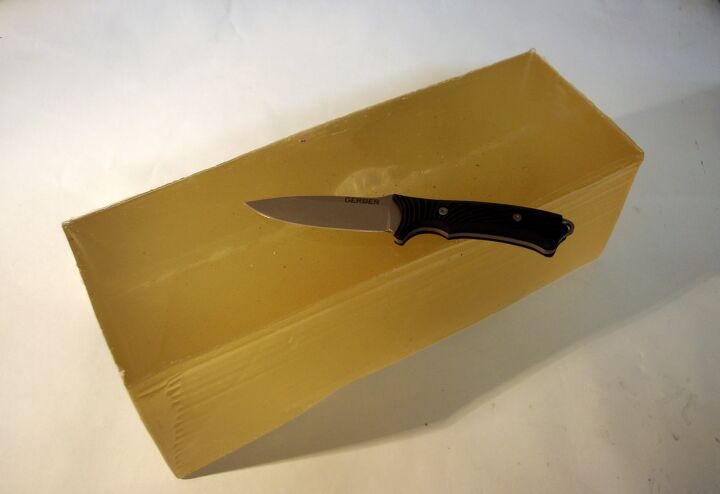

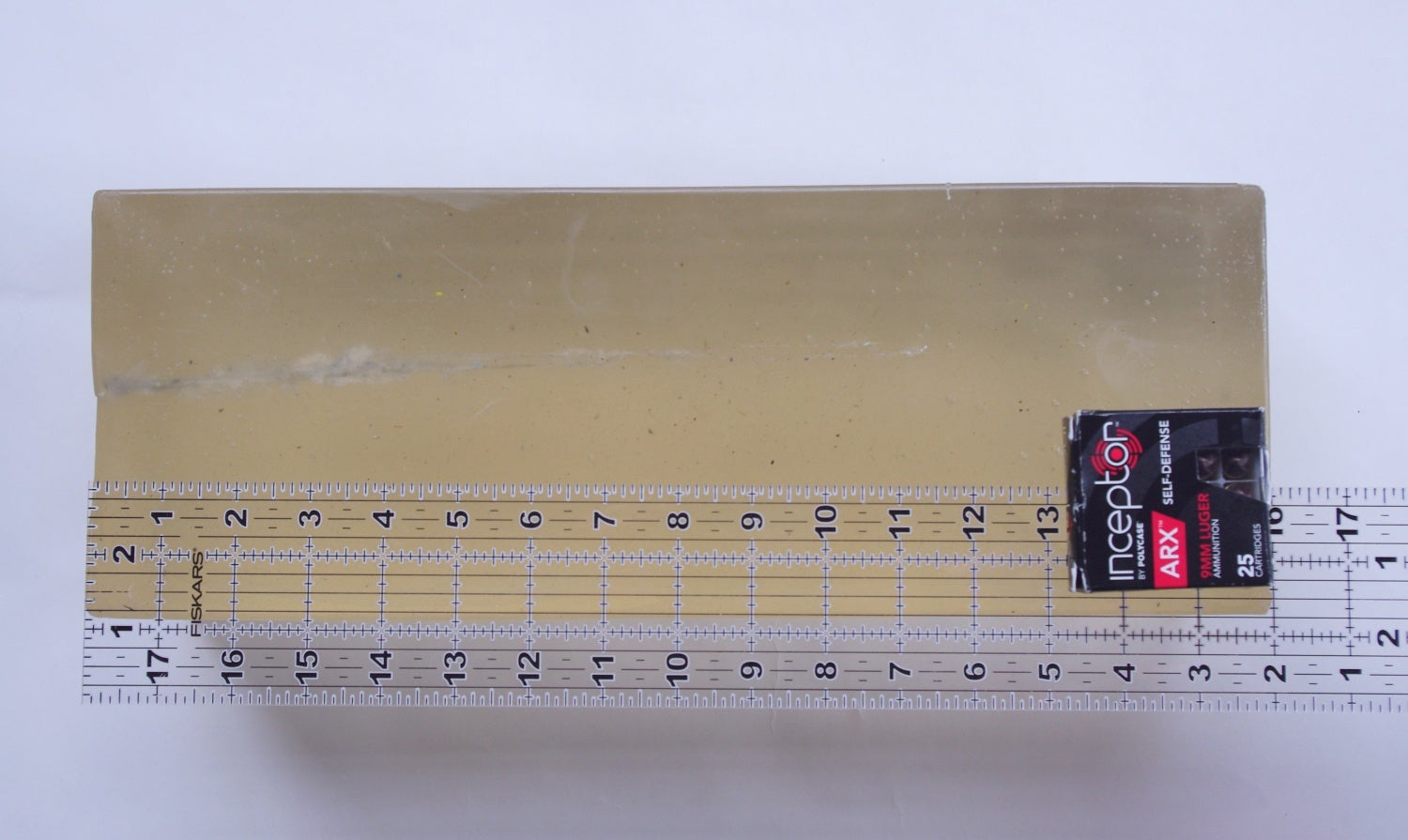

- The FBI block measures 6 inches in width by 6 inches in height by 16 inches in length.

- The FBI block weighs 17.2 lbs and is 9.43 liters.

- The FBI block is temperature stable does not require refrigeration. (The gel will melt around 240 Fahrenheit)

- The block can be re-melted and is initially 100% clear.

- Additional gel can be purchased should your gel become soiled or ruined during testing.

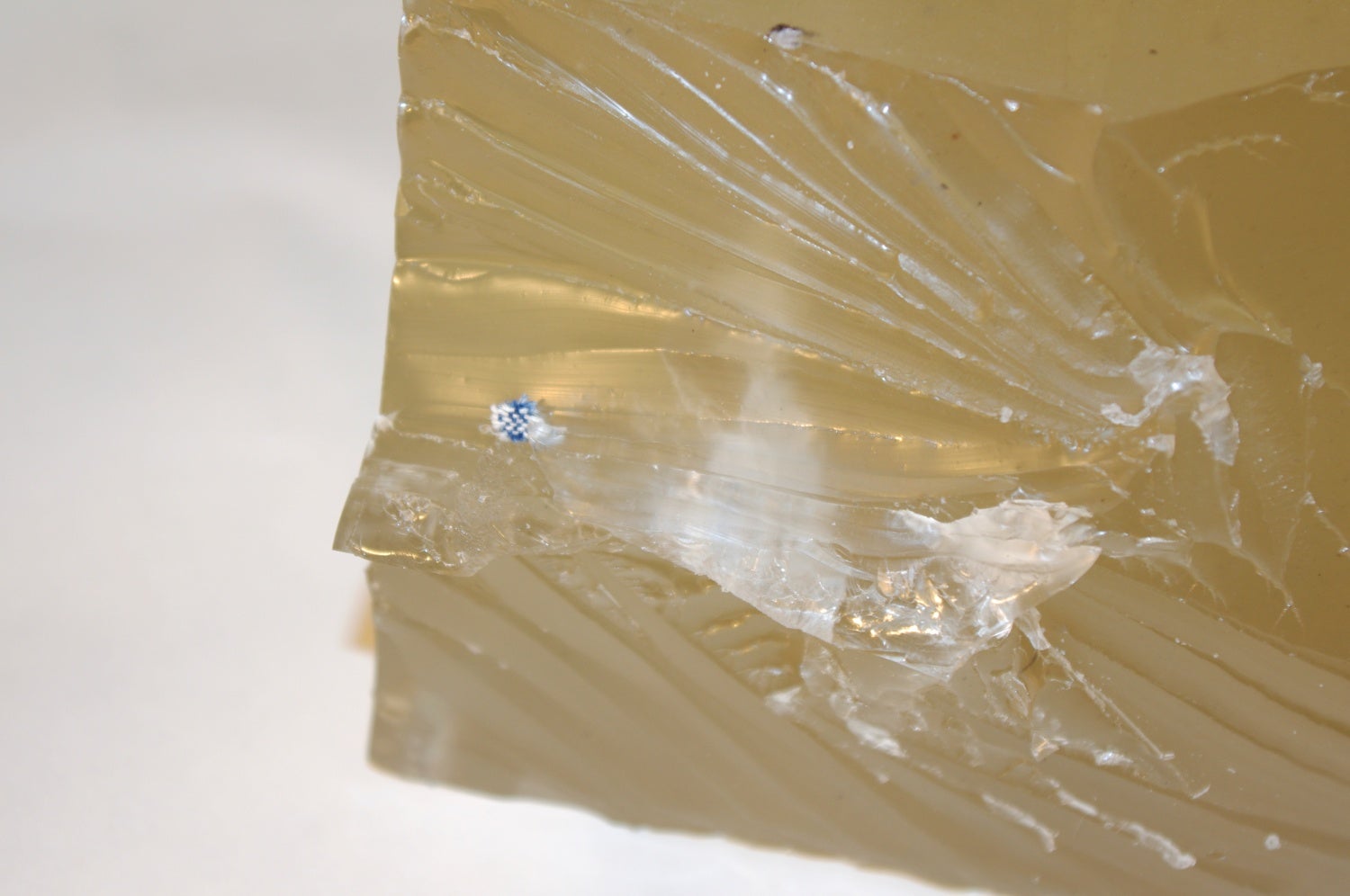

Like it’s namesake, Clear Ballistics gel starts out clear. As it is reheated it will turn yellow over time. The “ripples” on the exterior of the gel could have been removed with a heat gun. This was the first outing with these gels.

During our ballistic testing we re-melted the gels 7 times each. Since we had had two gels and we conducted 8 shooting session, we had 14 instances where we re-melted and re-formed the gels. Below is “how-to” tutorial on how to work with Clear Ballistics Gel as well as some tips and tricks we picked up along the way.

In order to re-melt Clear ballistics gel you will need the following items.

- Turkey Roaster. I used a Rival 14 quart 20 lb turkey roaster.

- Oven mits and stainless steel spoon

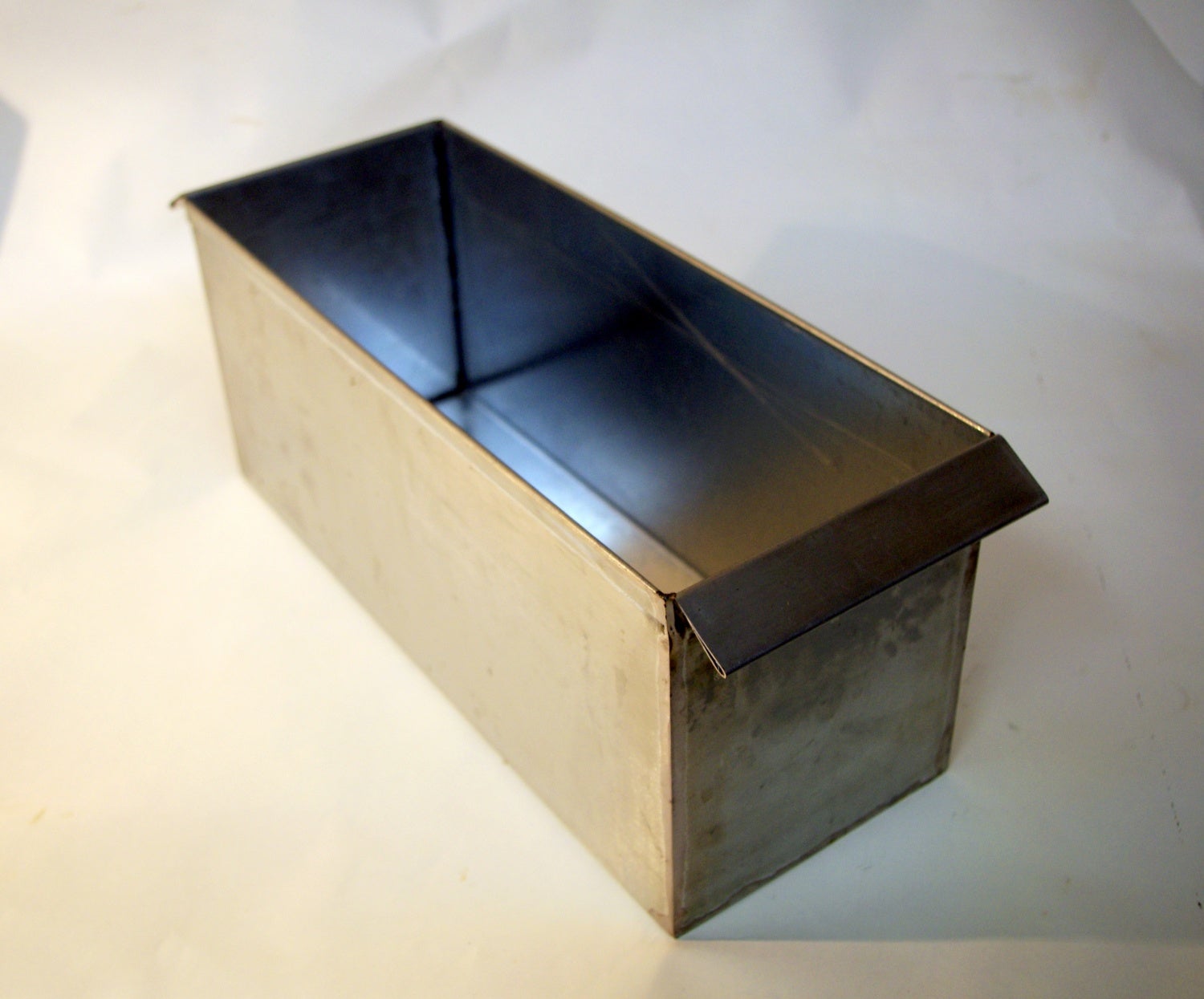

- Stainless steel mold from Clear Ballistics

- Large disposable aluminum roasting pans

- Aluminum Foil

- Respirator. I used a Sperian P1130 respirator. The respirator is rated to filter out 95% of oil containing aerosols. Clear Ballistics gel is an oil based product.

- Heat Gun

Heat gun, 14 quart turkey roaster, oven mits, large stainless steel spoon and FBI Block mold from Clear Ballistics.

In order to re-mold Clear Ballistics gel you will need a mold. You can probably make your own out of some steel or aluminum sheets. For this project we purchased the FBI Block mold. The mold is 16 inches by 6 inches by 7 inches. We purchased this mold from the Clear Ballistics website.

The first step to re-melting the gel is to clean up the gel. If the exterior is soiled with dirt you can rinse it off with warm water. If you get it wet, make sure to dry the gel off completely. If you melt wet gel you will permanently ruin it. After cleaning the exterior of the gel I cut the gel open and cleaned out the wound channels.

After cleaning the gel and making sure it is completely dry, cut the gel into small pieces. Be careful not to cut yourself. The gel can also be torn apart if you do not wish to endanger yourself with a sharp blade.

After tearing the gel into small pieces, load the gel into a clean turkey roaster. After plugging in the turkey roaster, set the turkey roaster to 260 degrees Fahrenheit.

As the gel heats up you will see smoke coming off the gel. Clear Ballistics states that their product is non-toxic. The first time I worked with the gels I inhaled a small amount of smoke and got a terrible headache. After that, I used a Sperain P1130 respirator when re-melting the gel. Clear Ballistics is an oil based product. The Sperian P1130 respirator will filter out 95% of oil containing aerosols.

I found the best place to melt the gels was on the deck of my home. The melting gels are not odorless and will give off smoke. I put a piece of cardboard down to assist in clean up should I accidentally spill any of the liquid gel.

After the gel has melted on the outside, use your metal spoon and break up the semi solid clump in the middle of the roaster.

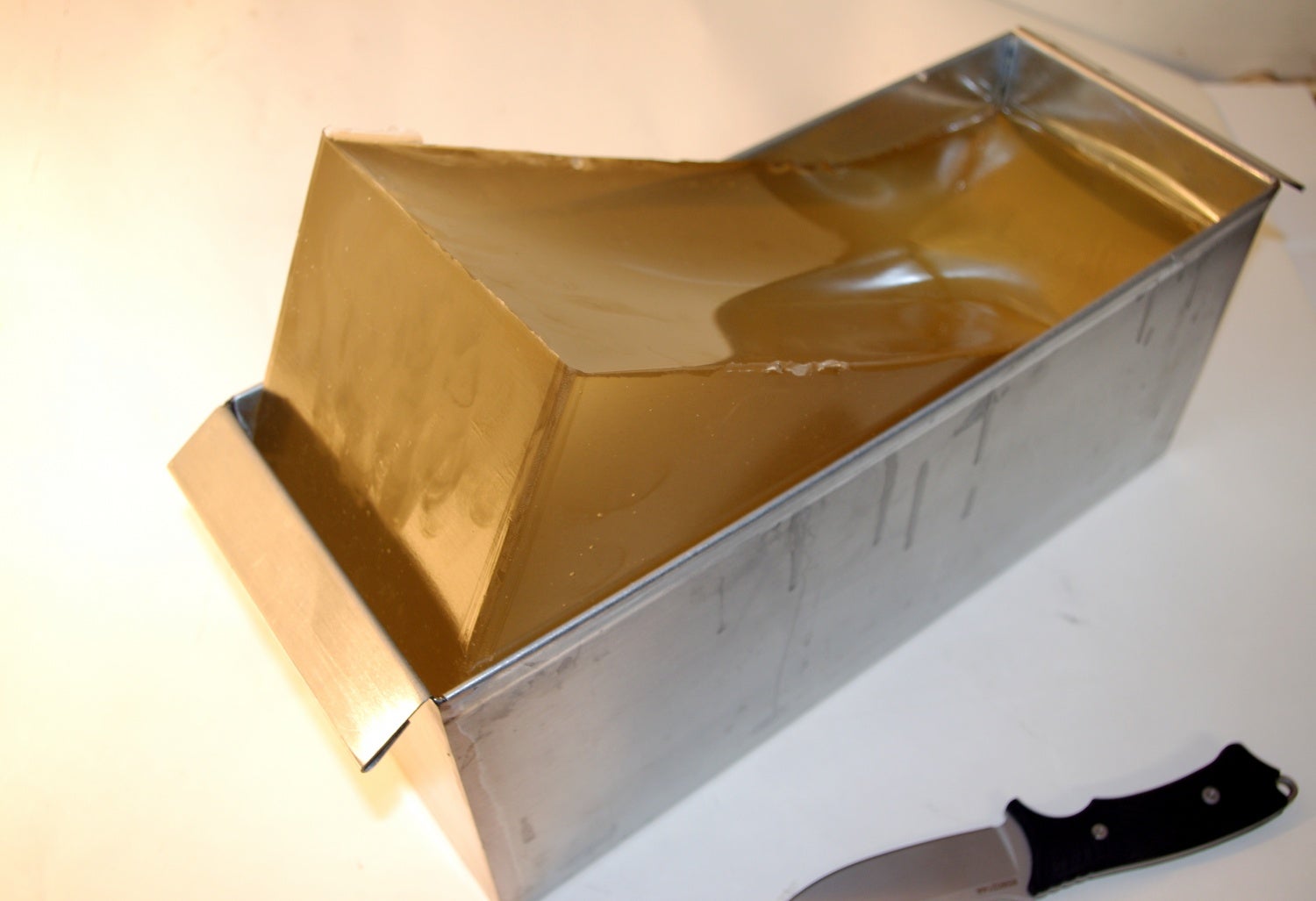

After the gel has completely melted, take your mold and place it on a large disposable roasting tray.

Using heat gloves to hold the roaster, pour the gel into the mold. Some gel will spill into the pan. Make sure you wear foot and eye protection. Please note, the mold will quickly heat up. Make sure the mold is not placed on anything flammable.

After you pour the gel, you will see large bubbles form in the gel. Grabbing the heat gun and an oven mitt, shake the mold while blowing hot air on it. This will remove most of the bubbles in the gel.

After you have removed all the bubbles from the gel, cover the gel with aluminum or tin foil. Your garage is most likely full of “creepy crawlers” who will land/fall into your gel.

As previously mentioned, when pouring the gel some will miss the mold and fall into the roasting tray. This will be a small amount. Let it cool and save it for your next re-melt.

I found that the gels typically required about 10-12 hours to solidify. If you need to speed this up you can put the gel in a cooler full of ice. I placed a board at the bottom of the cooler and placed a 2 inch layer of ice at the bottom of the cooler. Make sure the board is covered with ice. Add the mold with the gel in it. Carefully place ice around the mold. Do not get ice in the hot gel. This will ruin the gel. DO NOT close the lid, you will get condensation on your gel. Do not put the hot gel and mold in the freezer or refrigerator, you will get condensation on your gel. I found that the gels will solidify in about 4-5 hours.

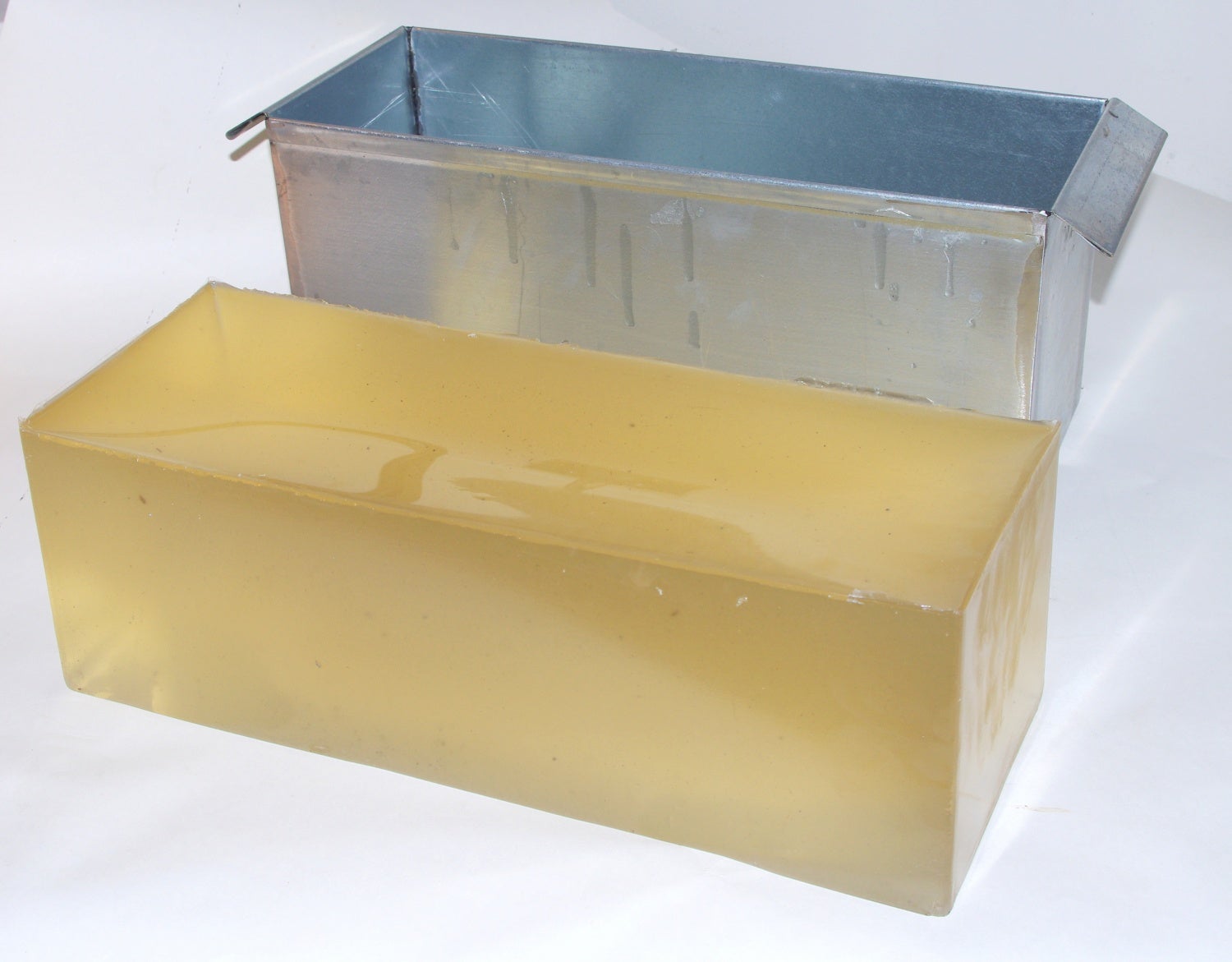

After the gel has solidified and the gel and mold have cooled to room temperature it is time to remove the gel from the mold. Clear Ballistics sells a product that helps remove the gel from the mold. I did not use this product. I do not feel that you need it.

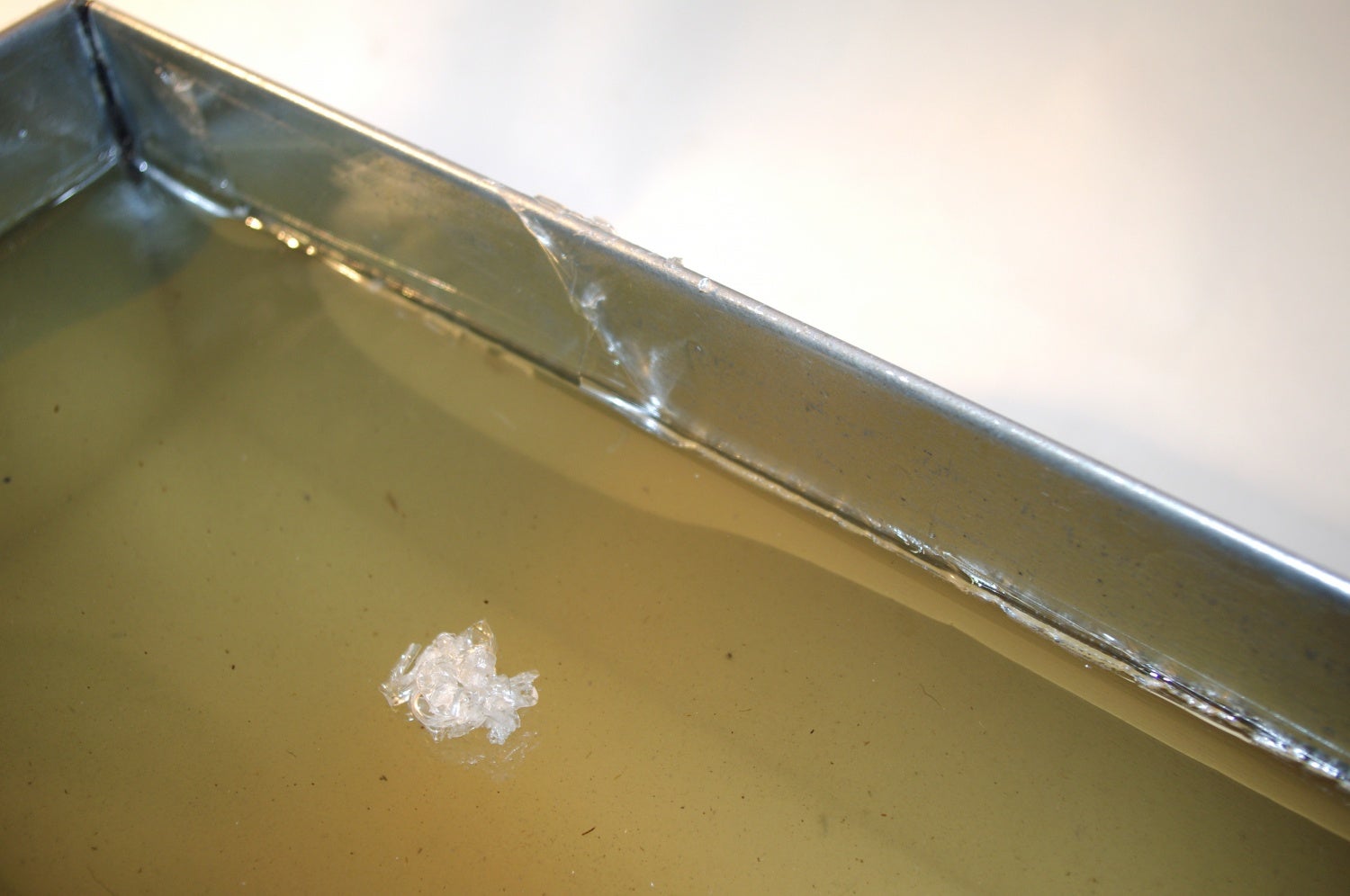

When removing the gel, you will see some of the gel on the walls of the mold. Run a knife around the edge of the top of the gel.

Peel away the thin layer of gel that was created during the pouring process. You can use this for future melts.

After cutting around the edge, and removing the excess gel, push down on the edges of the gel, releasing the gel from the mold.

Slowly work one side of the gel out of the mold. Stand the mold up on its side and gently pull the gel out of the mold. Any small tears or hand prints can be cleaned up with a heat gun.

A nice clean gel ready to go. You can see on the right side of the gel, some excess gel that I failed to cut off. You can pass over these areas with a heat gun and melt them into the block.

If you followed this series of articles, sharp eyes readers probably noticed a gradual yellowing of the gels. Clear Ballistics states that the gels can be remelted 6 times before they start to turn yellow.

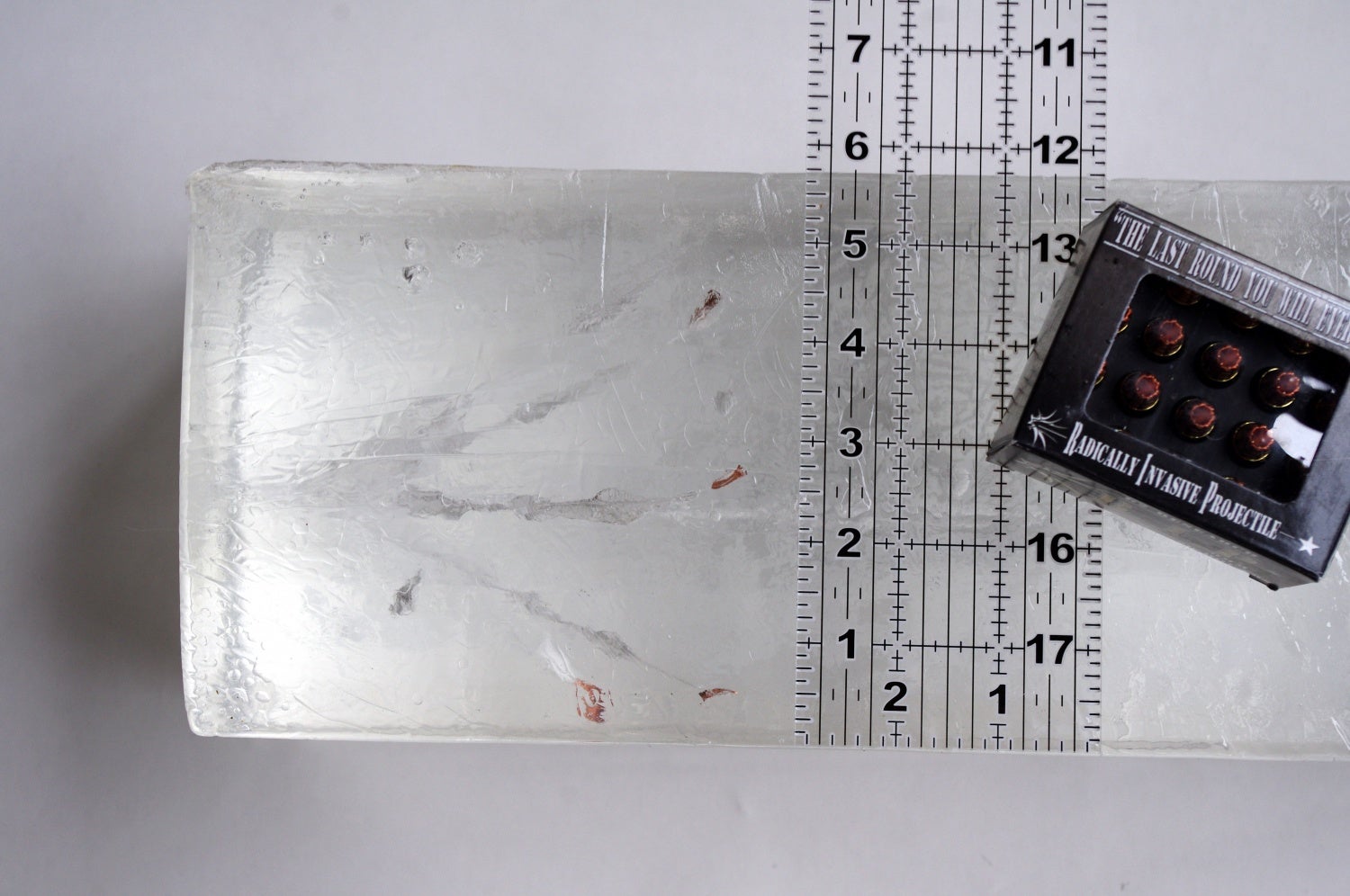

This picture was taken after the very first shoot. Note the clarity of the gel . Had I gently gone over the gel with a heat gun to smooth out the ripples from being in a cardboard box, this gel would be near transparent.

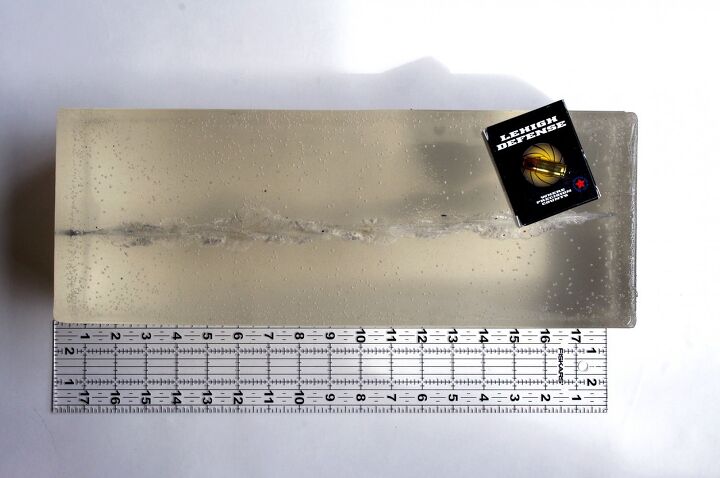

This picture was after our 4th shooting session. At this stage of testing this gel would have been reformed three times. The gel was still fairly clear.

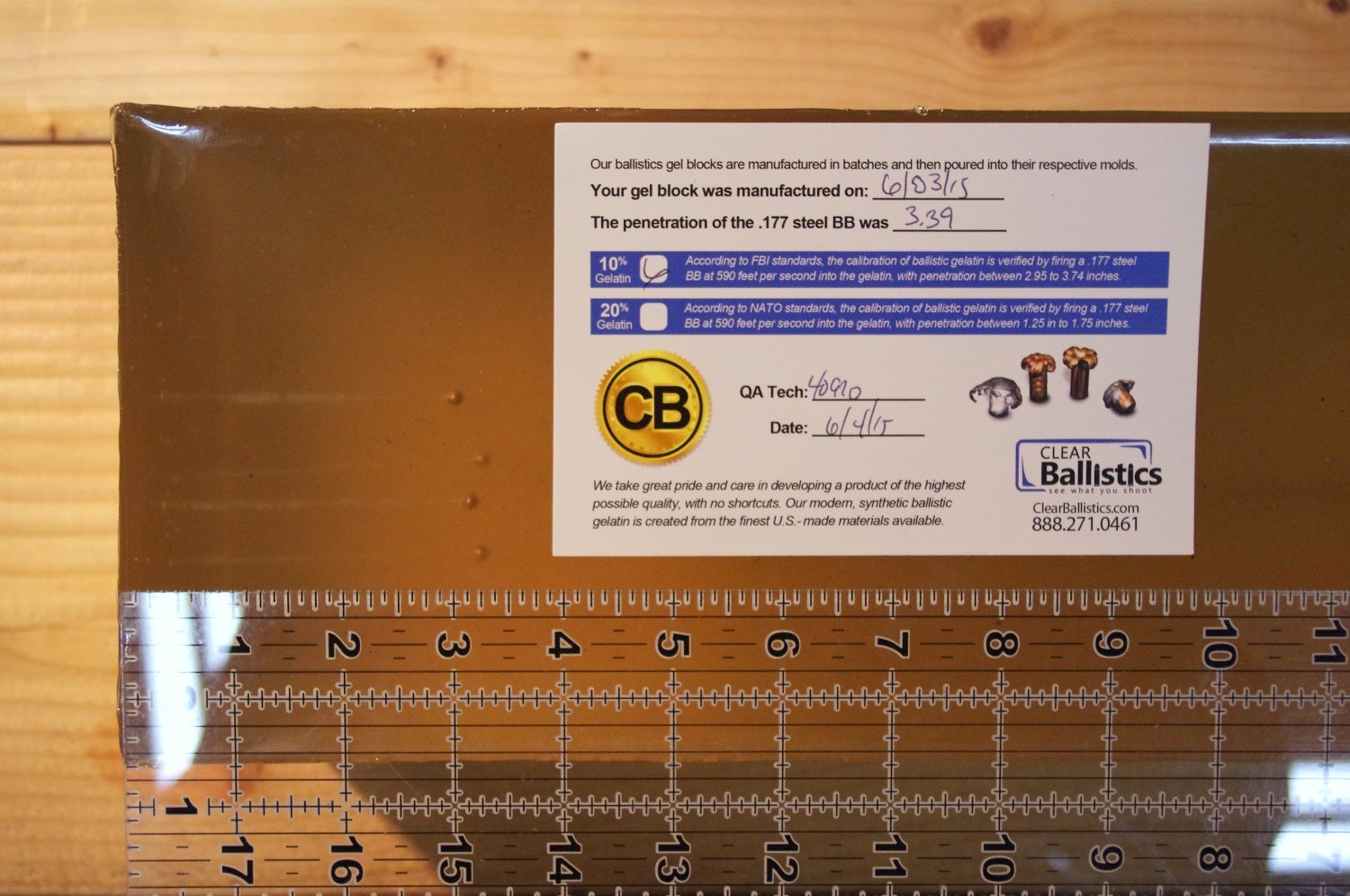

This picture was taken after out 8th range session. This gel would have been reformed seven times. Very discolored and dirty. The next time this gel gets melted, I will pour it through a metal filter to clean out small debris.

A note on calibrating Clear Ballistics gel.

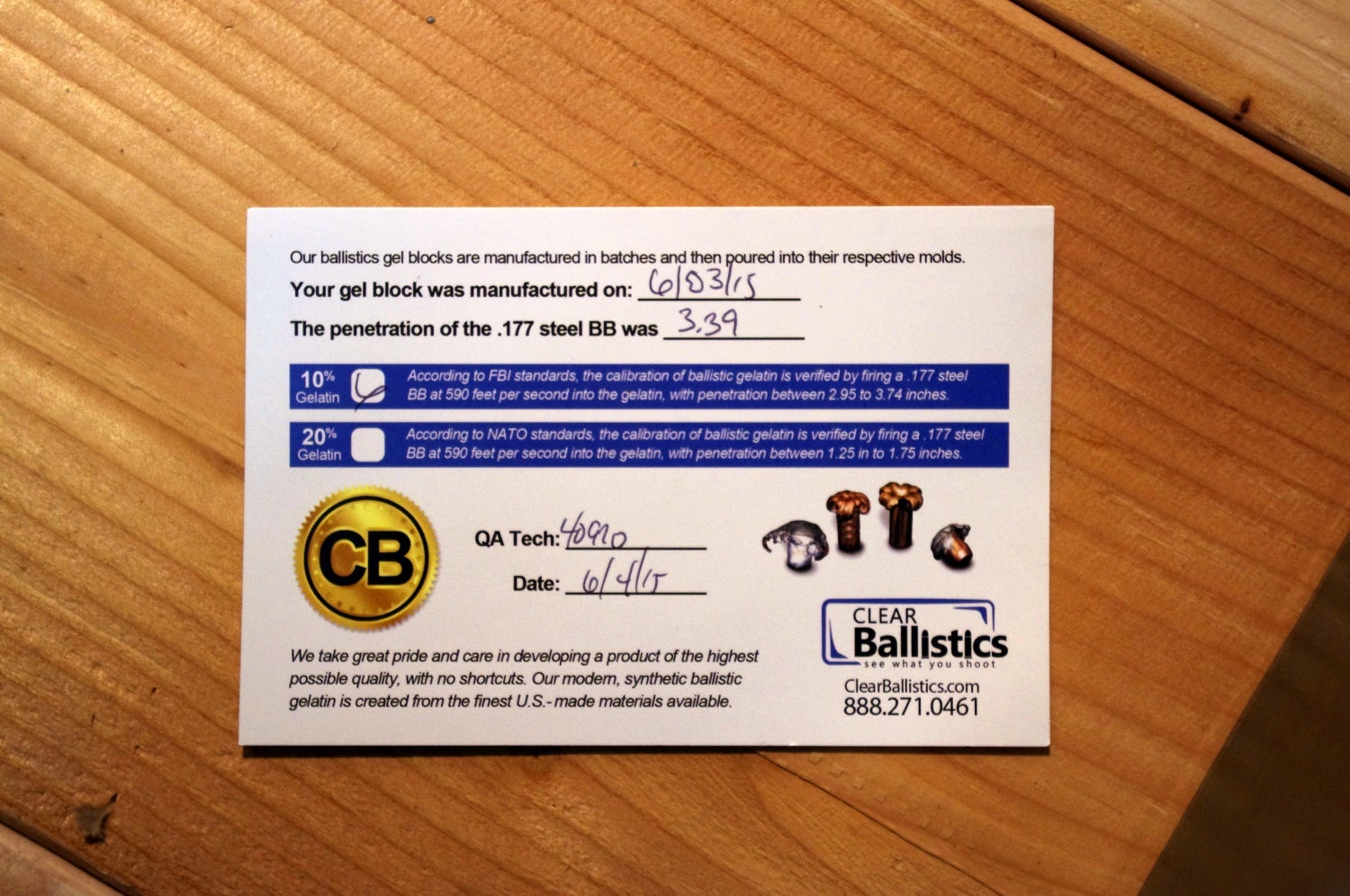

Normal ballistic gelatin is made from collagen. Collagen is a structural protein found in the connective tissue in animals. Ballistic gelatin is designed to mimic the density of human muscle tissue. Unlike Clear Ballistics oil based ballistic gel, collagen based ballistic gelatin needs to be kept at very specific temperature. Both oil and collagen derived gels are calibrated by firing a .177 caliber BB into the block and measuring penetration. The Clear Ballistics gel that we were provided for testing mimicked 10% Gelatin. The FBI standard for 10% gelatin calls for a .177 caliber BB fired into the gel traveling at 590 feet per second. The BB must penetrate 2.95 to 3.74 inches into the gel.

When you buy Clear Ballistics Gel, a technician from Clear Ballistics will test the density of the gel. Clear Ballistics tests the density of the gel by firing a .177 caliber BB into the gel. The BB must be traveling at 590 feet per second and penetrate at least 2.95 – 3.74 inches into the gel. This card was provided with the ballistics gel.

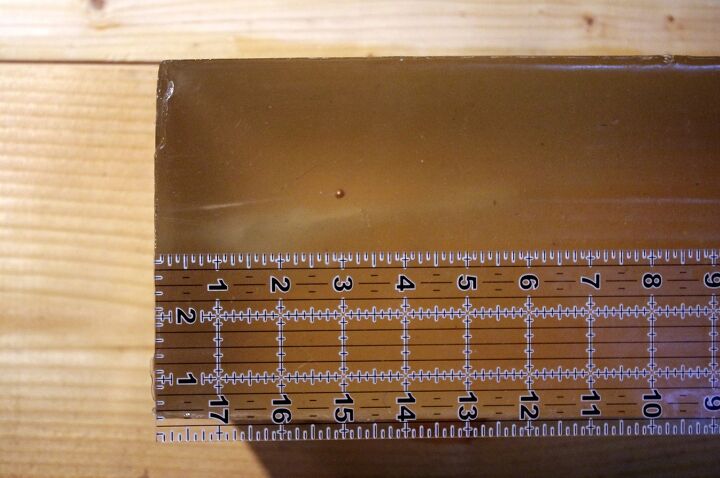

Using a Daisy Powerline 901 BB gun and a chronograph, each gel was checked after being re-formed. On hot days, the BB’s would penetrate about .5 inch more. The gel in the picture was re-formed 9 times. It was about 45 degrees Fahrenheit in my garage when I tested this gel. The BB’s penetrated 2.95 to 3.25 inches. After being melted 9 times this gel still has the appropriate density for ballistic testing.

This gel had been re-formed 8 times. The BB penetrated exactly 3 inches. This gel has the appropriate density for ballistics testing.

After reforming the gels 16 times, we came to the following conclusions.

- Do not attempt to do this in your kitchen oven. You will smoke up your house and leave oil residue in your oven that will have to be cleaned out by hand.

- Simply tearing up the gels, placing them in the mold and popping the mold in the oven did not work. I found that the heat did not transfer very efficiently into the mold, and the gel in the middle of the mold did not liquefy. The only answer would have been to turn up the heat. This in turn would have burned the top and outer layers of the gel.

- Clear Ballistics claims their gels are non-toxic. Wear a mask, I got a terrible headache after inhaling some smoke coming off the melting gels.

- Clean your turkey roaster after every use. Remaining oils will burn and discolor your gel.

- Crock pots will not work very well. Get a large turkey roaster.

- You can fuse the gels together for rifle testing, by heating the ends of the 16 inch gels and melding them together.

- Do not get the gels above 280 degrees Fahrenheit. They will turn yellow. Debris can be filtered out of the gels using a metal filter.

- You can wash the gels, but make sure they are not wet when you melt them.

Clear Ballistics has a wonderful product. I look forward to testing some of my hunting rifle rounds. As always, tips, gripes and jokes are welcome in the comments below. A big thank you to Clark Amory for sponsoring our Ammunition Test.

Your Privacy Choices

Your Privacy Choices