Here are pictures of a neat little submachine gun prototype sent in. It uses minimal components and can be constructed with very basic tooling in short order. The builder made the example pictured as a non-firing replica for obvious legal reasons.

The criteria was for a design which can match similar commercial counterparts in terms of compactness, durability and aesthetics whilst being infinitely cheaper, quicker and easier to produce. It uses Sten mags, a spring from a grease applicator tool, standard lock collars and a rubber bicycle grip among other easily obtainable bits.

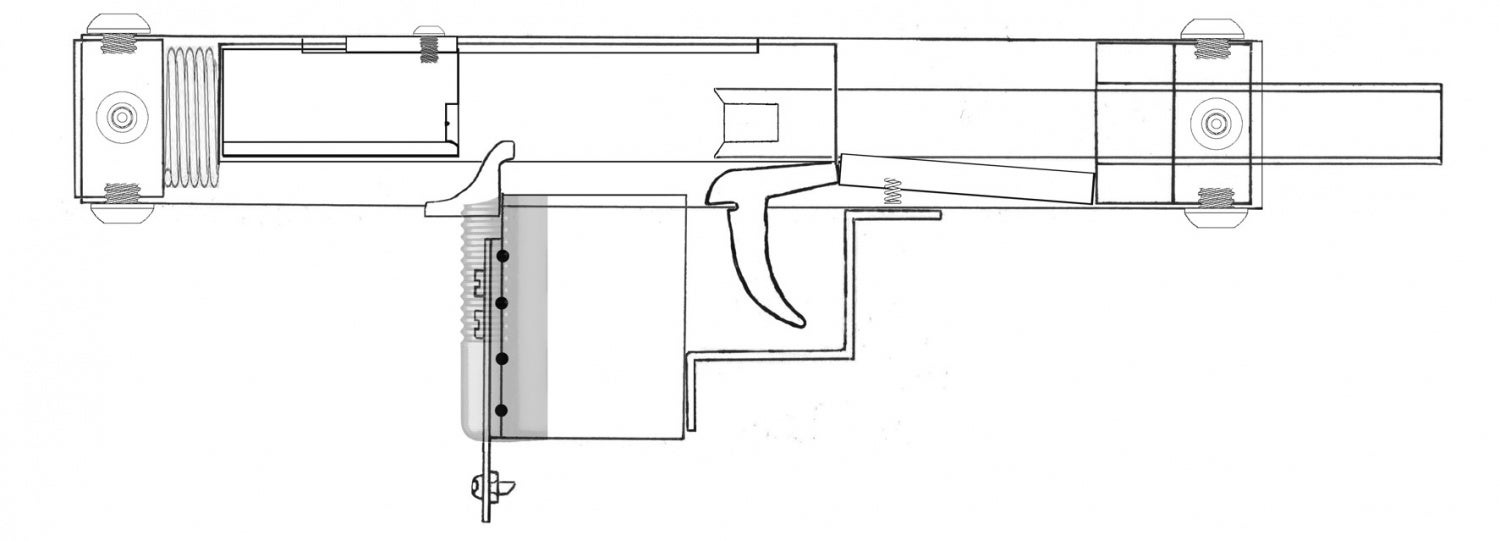

It strips down to only nine main components which are all housed in a single receiver tube. Internal arrangement is Illustrated below:

Some may recognize it as being a basic simplified copy of the Texas made MP2 SMG seen wielded by Arnold in the film Raw Deal.

Edit: Here is a PDF detailing it’s construction.

Your Privacy Choices

Your Privacy Choices