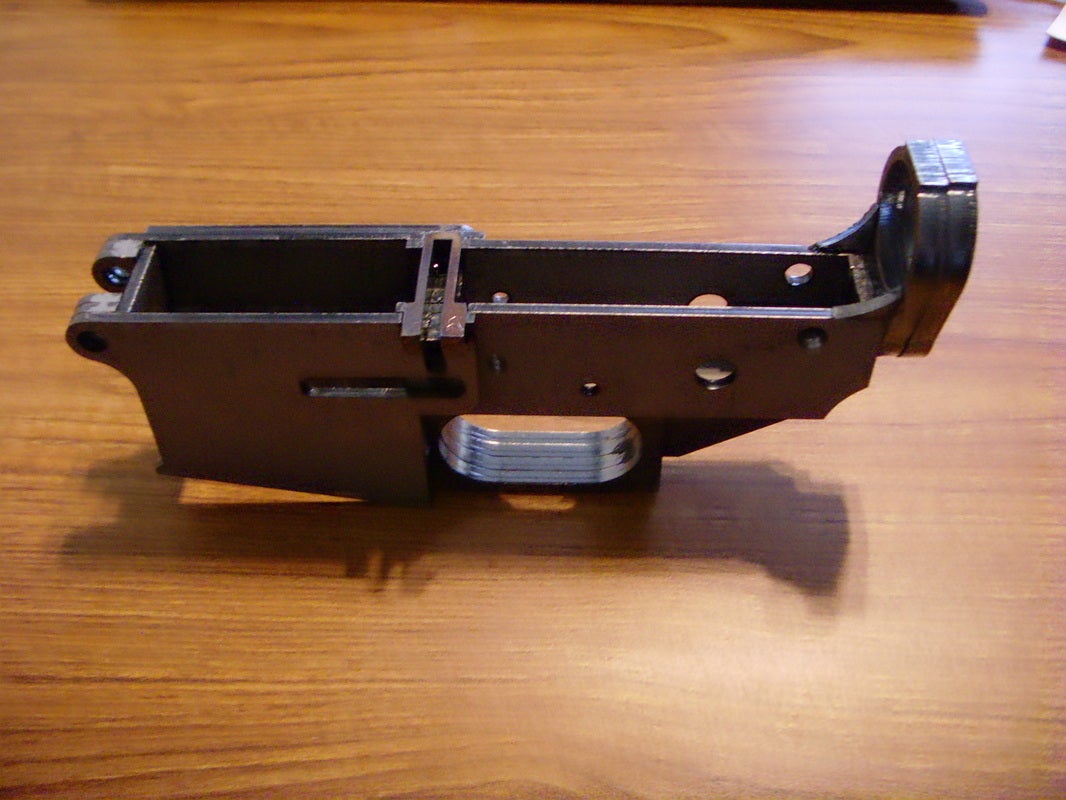

For the ultimate do-it-yourself-er or someone still waiting on their Ghost Gunner, The Flat Spot has a nifty weld-your-own AR receiver out of mild steel. The kit is not 100% weld and go, as it does require some work.

Details on construction for The Flat Spot:

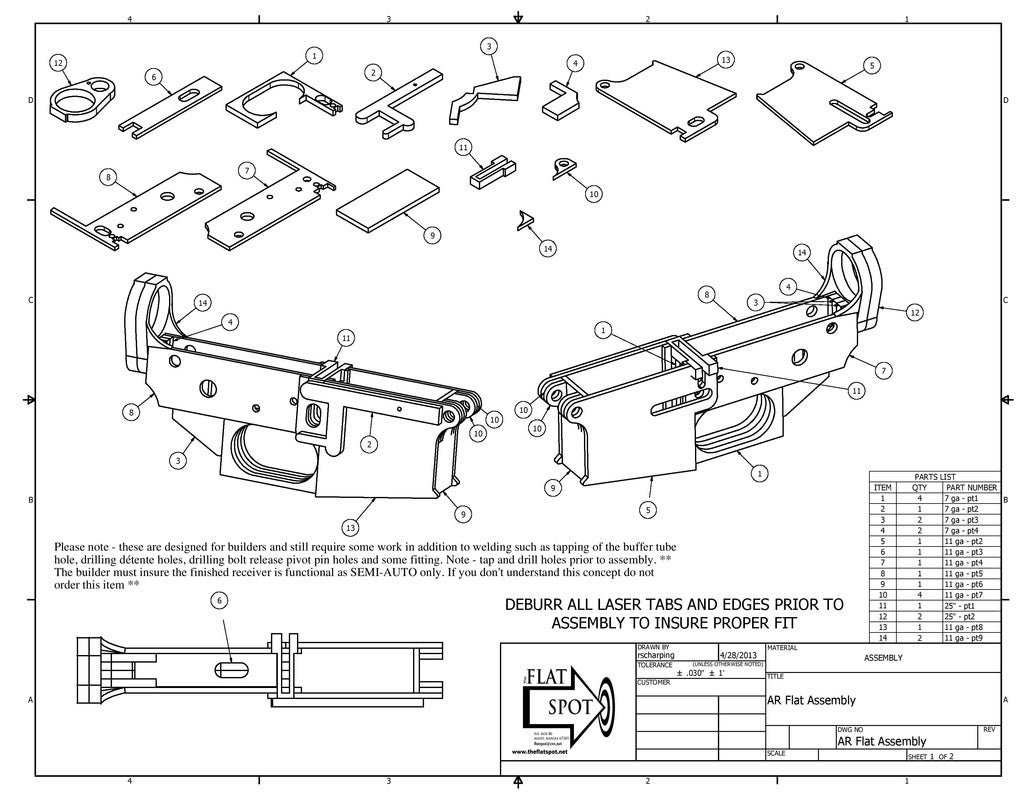

AR-15 RECEIVER FLAT(weldable) mild steel construction for $28.00 Combine with other products we offer to save. $6 unlimited flat rate shipping. Please note – these are for builders and still require some work IN ADDITION TO WELDING such as tapping of the buffer tube hole (many builders choose to simply weld a castle nut on the rear of the buffer tower instead of tapping), drilling détente holes, drilling bolt release pivot pin holes and some fitting. Note – tap and drill holes prior to assembly. ** The builder must insure the finished receiver is functional as SEMI-AUTO only. If you don’t understand this concept do not order this item ** Deburr the tab from all parts to insure proper fit during assembly. Please see the cad drawing files below for assembly instructions.

The kit is available for $28 with $6 flat rate shipping. Many other kits are also available including parts for AK’s, UZI’s, and MAC-10s

Your Privacy Choices

Your Privacy Choices