Its not everyday that someone introduces a new line of ammunition, much less one that is injection-molded, lead-free, and claims that the ideal self-defense round does not expand. But, today (er, yesterday), was the day and PolyCase, a company out of Savannah, Georgia, introduced its Inceptor line of ammunition.

The ammunition line includes four distinct projectiles:

- ARX – Non-expanding, defense ammunition.

- RNP – Round nose, precision.

- Firefly – Tracer

- TNP – Flat noted, precision.

Like other frangible ammunition, PolyCase has lighter rounds for higher velocities, likely a byproduct of their chosen Cu/P material (its not as dense as lead). As such, shooters will get a flatter shooting round.

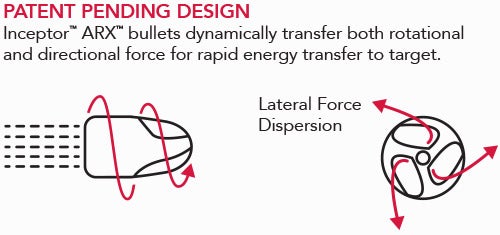

The claims surrounding the ARX line piqued my interest the most. PolyCase proudly touts it as “revolutionary self-defense technology” that its shape leads to a “hydrodynamic ram effect” on target that maximises “lateral force dispersion”. Some fancy words for what sounds like “we create a big temporary wound cavity.”

I’ll let PolyCase do the talking:

the ARX™ is a new bullet in every sense of the word. From the way it’s manufactured, to its shape to the way it transfers energy to the target. To understand the ARX™, one needs to forget nearly everything they’ve been told about bullets.

The ARX™ bullet is designed to not expand. The ARX™ is injection molded from a specially blended lead free, copper/polymer matrix that is designed to be tough enough to penetrate soft targets and tissue, but when it encounters tougher barriers it is designed to break up to reduce the risk for collateral damage due to over penetration.

Even though the ARX™ is lighter and travels at much higher velocities than conventional bullets, it will not defeat soft body armor.

Even the heaviest clothing barriers have no effect on the terminal performance of the ARX™ bullet. The ARX™ penetrates straight until it encounters soft tissue. Upon entering soft tissue, the specially designed grooves in the nose harness the rotational energy of the bullet during the initial 6” of penetration.

The features in the nose of the ARX™ bullet also create hydrodynamic ram which compresses the fluid-filled tissue ahead of the bullet and creates an envelope around the bullet.

At this point the bullet tumbles on a helical path and continues to create a large temporary cavity. As the bullet penetrates it tumbles in a controlled, predictable fashion that delivers very consistent terminal performance that equals or exceeds conventional hollow point designs. In soft tissue, the ARX™ is designed to penetrate 12” to 14”, every time.

ARX™ is safe for use in suppressors – it will not disintegrate in the barrel like sintered bullets.

Here’s the video of their 9mm ammo in slow-motion:

Note it does not show the permanent wound cavity, just a temporary stretch cavity.

My take?

This is a bunch of marketing gobblety-gook for ammunition that does not leave a significant permanent wound channel but has some redeeming features like some frangibility.

I’m not saying I am passing judgement against it, but I want to see good videos with the full test and outside opinions before I ever carry it. Right now, it looks like a R.I.P. with lots of sizzle and no support.

Full Press Release Below

PolyCase Introduces Inceptor Ammo Line

Savannah, GA– PolyCase Ammunition, makers of ammunition for the 21st century, announces the launch of its revolutionary Inceptor™ by PolyCase line of ammunition. Lead free, environmentally safe and range compliant, Inceptor by PolyCase ammunition features their patent-pending Cu/P™ projectiles, produced by a patent-pending, technologically advanced and fully automated injection-molding process, loaded to SAAMI specs in high quality brass cases.

“PolyCase Ammunition approaches ammunition from a different method, leveraging highly engineered designs, advanced materials and patent-pending precision injection molding techniques to create polymer-based components with sound terminal performance. We carefully consider and determine all aspects of how our products are made, to how they function, and own and control the research, development, rapid prototyping, testing and manufacturing processes. From the drawing board up to the finished product, we produce components that are easy to load, durable and highly effective,” said PolyCase Founder and CEO, Paul Lemke.

PolyCase Ammunition’s Cu/P material –– a proprietary lead-free copper alloy with a high-tensile strength nylon binder developed specifically for projectiles –– produces lighter, faster, extremely accurate yet cost competitive bullets. Those bullets, engineered to display uniformity in concentricity and weight, fly faster and flatter, resulting in higher velocities and match-grade accuracy. Initially loaded in the traditional pistol calibers Inceptor by PolyCase cartridges feature four bullet profiles:

The non-expanding patent-pending, ARX™ (Advanced Rotation eXtreme) establishes itself as the ideal self-defense projectile with a revolutionary design that transfers both rotational and directional force to targets and produces exceptional penetration while mitigating the risk of over penetration. Currently available in the traditional pistol calibers of .380 Auto, 9mm, .40 S&W and .45 Auto, rifle cartridges ship in the next few months. Watch the ballistics test of the 9mm Luger 74 Grain ARX here.

The extreme precision RNP™ (Round Nose Precision) available in .380 Auto, 9mm and .45 Auto & TNP™ (Truncated Nose Precision) in .40 S&W deliver predictable performance at the range and approved for use on steel targets with significantly reduced ricochet. See the .40 S&W TNP in action here.

A bright tracer compound makes FireFly™ visible in full daylight, allowing shooters to track their shots from muzzle to target. Engineered for training and tactical applications, Inceptor by PolyCase FireFly™ does not foul or damage the barrel of your firearm and comes in .380 Auto, 9mm, .40 S&W and .45 Auto. Watch the FireFly™ tracer shot at dusk here.

Safe for handguns, rifles and suppressors, Inceptor by PolyCase Ammunition produces faster velocities, reduced recoil and lower muzzle rise, allowing for quicker follow-up shots and making a day at the range fun for everyone especially beginners and small statured shooters. Environmentally conscious and non-toxic, Inceptor by PolyCase line of ammunition stands as the choice for effective, reliable, accurate and lightweight, lead-free ammunition for the 21st century.

For more information and to view the entire product line visit: www.polycaseammo.com or www.facebook.com/PolyCaseAmmunition or email PolyCase Ammunition at info@polycaseammo.com. For media inquiries please contact: plemke@polycaseammo.com

PolyCase Ammunition is a precision injection molding company located in Savannah, Georgia. Veteran-owned and operated, PolyCase develops, manufactures, markets and sells premium, patent-pending, injection-molded, competitively-priced small arms ammunition products to sportsmen and Law Enforcement professionals. Made in the USA, using over ninety years of collective advanced design, materials and manufacturing experience; PolyCase brings technologically advanced, yet competitively priced ammunition options to the shooting public. For additional information, visit www.polycaseammo.com.

Your Privacy Choices

Your Privacy Choices