William Smalley of Remington (and formerly of Para Ord) has been working on the R51 since its inception. I spoke with him about the R51’s troubles, and its planned return to production in early Summer this year. William is a “gun guy”, not a marketing associate or a booth runner; when a friend and I were looking at the interaction of the grip safety and the trigger, William field stripped the gun right in front of us and let us see how the mechanism worked.

It was difficult to control myself when handling the R51 with the laser module. The urge to say “pew pew!” was overpowering.

William said the problems that plagued the initial R51 release – including out of battery firings in some examples, and especially tight locking blocks in others – were the result of a tolerance stacking error. Even with today’s high-precision manufacturing techniques, every part of each individual gun is slightly different from the same part in the next gun, and to allow for the mass manufacture and assembly of weapons, each dimension of a part is held to a standard: No bigger than X, no smaller than Y. If enough parts are close enough to X than Y, or Y than X, an individual pistol can have what is called a “tolerance stacking” problem: The parts don’t fit right, and problems result.

According to William, this is what happened to the R51: The locking block that is the signature feature of the R51’s hesitation-locked design is a low-tolerance part – in other words, X and Y are very close together. This means that if the dimensions of these locking blocks are not controlled correctly, tolerance stacking can quickly result.

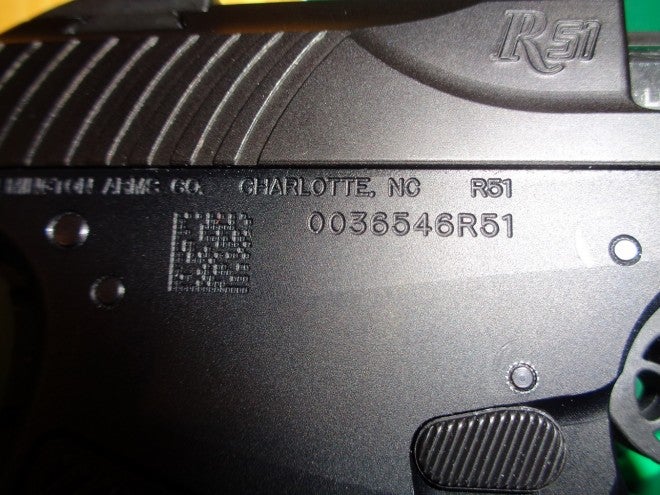

Owners of the new R51 won’t notice much different than the old weapon; the new guns say “Huntsville, AL” on the side instead of “Charlotte, NC”, since Remington is closing the Charlotte plant, and moving all production to its facility in Huntsville. William is confident that Remington has put the time and work needed to solve the tolerance-stacking issue, and even with the blood, sweat, and tears (and four magazines!) that the new R51 comes with, he says the expected MSRP will be around $400.

The guns at the Remington booth were all older models from the Charlotte plant. All R51s from the new production run will be made at the Huntsville plant. The place of manufacture is the primary way to distinguish between first and second production run guns.

As the beaming owner of an original .32 ACP Remington 51, made between 1921-1923, I really want to see this pistol succeed. Given its initial release, though, only time will tell.

We are committed to finding, researching, and recommending the best products. We earn commissions from purchases you make using the retail links in our product reviews. Learn more about how this works.

Your Privacy Choices

Your Privacy Choices