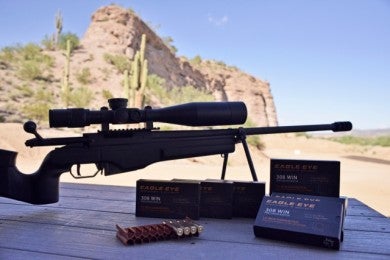

I had the opportunity recently to attend a demonstration of a new ammunition brand coming on the market, which is dedicated to maximum accuracy and consistency. It’s called Eagle Eye, and I came away pretty impressed…

A Different Philosophy

Eagle Eye Ammunition wasn’t started by a businessman or an opportunistic investor or a corporate committee – it was started by a scientist. That should pique your curiosity – I know it perked up my ears. Justin Brown, the surprisingly young company President, looks like he belongs in Silicon Valley, and speaks like he belongs in front of the blackboard in a college calculus classroom. What does this have to do with ammunition? Everything, because ammunition manufacture is entirely an exercise in consistency and precision.

The idea behind Eagle Eye is to take ammunition manufacture, an industrial process that hasn’t changed much since World War II, and subject it to a modern understanding of quality and process control. Have you ever wondered why it is taken for granted that handloading will produce more consistent ammo than factory production? As a society we have been perfecting the science of making identical copies of things ever since the M1819 Hall Rifle established truly practical interchangeable parts. Is it really true that with nearly 200 years of practice we still can’t have industrial ammo production match the quality of a guy in a room with a commercial digital scale?

No, we can do it – but nobody bothered to until Eagle Eye.

Eagle Eye guarantees 1/2 MOA accuracy with both they .308 and .223 ammunition, and it’s not just marketing BS. The short version of how they do this is that they test ammo continuously during production and stopping the line any time something starts to deviate too much. Not when it falls out of spec, but when it is statistically trending away from the expected standard. The testing is done with real rifles (Tikkas, mostly) in sleds in an indoor tunnel range at 100 yards.

Warning – Science Ahead!

When Justin discovered that I have an engineering degree and a basic understanding of industrial process control, his eyes lit up and his brain kicked into overdrive. He has a far deeper understanding of the subject than I do, but I was at least able to keep up with the main concepts. I think it is worth taking a moment to describe the statistical science behind this company, because that is really the heart of what makes it so good. However, it may cause your eyes to glaze over – proceed at your own risk.

The simple and old-fashioned method of quality control is setting a standard and then testing the finished product to see if it is in spec. If it isn’t, you throw it out. That is a wasteful process, because by the time you discover that something is wrong you have already made a lot of product that is now scrap. So the spec is often set rather generously to avoid scrap, and the testing is often used to sort the really good product from the just barely acceptable. If a company were a bit unscrupulous, they might then make sure that the best product batches went to the high-visibility clients and other influential trend-setters, and sell them lower grade material on the regular commercial market to folks whose opinion isn’t so important. Not a good situation.

With modern SPC (statistical process control), variables are measured throughout the production process, and carefully tracked. A baseline can be determined for any given step in to process – for example, we know that the standard deviation in measurement X is, say, 5mm. Each measurement at that step of the process is plotted on a chart and the trendline calculated. It becomes immediately mathematically apparent when the measurements start to show more variation that expected, even before the measurements start to fall out of spec. So if any measurement between 2 and 3 is acceptable and in spec, but I start to get a lot of 2.80 and 2.90 and 2.95 data points, I know something is wrong before anything has been produced out of spec, and I can stop the machine to determine what is causing the problem and fix it. In a product manufactured under an effective SPC regime, the final end-product testing is pretty much a formality, instead of being the primary quality determinant.

This is what allows Eagle Eye to make the ambitious claim of 1/2 MOA in every box and stand by it. They have quality machinery coupled with a thoroughly modern mathematical quality control process and an ambitious goal to provide the best possible ammunition for people who need it, like competitive shooters and law enforcement agencies. They produce their own cases from scratch (from a flat brass disk, no less, instead of a preformed cup). They produce their own projectiles for the .308 ammo (the .223 currently uses a Sierra projectile, but Eagle Eye’s own .223 bullet is on the way). They monitor the exact composition of the brass for both cases and jackets, because slight changes can ripple into inconsistencies in wall thickness or concentricity. They use Vihtavuori powder, because it’s the best available. They use CCI Match primers, because, as Justin explained to me, their laboratory testing showed no statistically significant difference between those and anything Eagle Eye could have produced in-house.

In the Real World

Anyone can talk a good game, but the truth will come out on the range – and 1/2 MOA is a pretty bold claim. That’s a standard beyond the capability of a great many rifles and shooters (myself included). So Eagle Eye invited me out to a range demonstration with some rifles and shooters that could truly wring the full potential out of their ammo. In particular, they had Kelly Bachand (US Rifle Team member and multiple title holder) and Glenn Dubis (Olympian and multiple world record holder) shooting a Sako TRG-22 at 100 yards. Here are the results:

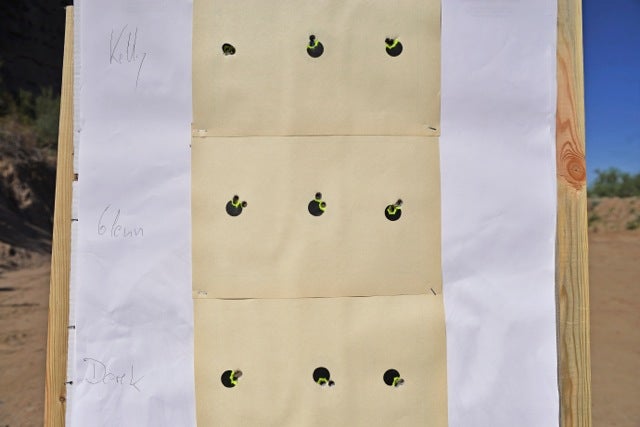

Eagle Eye .308 test targets. All 3-round groups shot at 100 yards in front of witnesses. In the bottom set, each group used one cartridge from each of 3 different lots of ammo.

That third row of shots are particularly impressive, as they are 3-round groups each using cartridges from three different lots of ammo. With Eagle Eye, you don’t need to stock up on a single lot number to get consistency – every box is the same down to a level that only the absolute top handful of shooters will be able to determine.

While we stood back and watched, they shot these groups right there on the spot, and we ran a bunch of ammo through a chronograph. The best results came in at a standard deviation of 8fps (extreme spread 21 fps) in 5 rounds of .308, and the worst batch had a standard deviation of 21fps (also .308). The typical standard deviation was in the low teens, across a variety of rifles.

Practical Implications

Will Eagle Eye mean I start shooting half minute groups with a 1960s Ishapore 2A1 Enfield in .308? Um, no. Your group size won’t be any better than the worst performing element of the shooting trinity of gun, ammo, and shooter. Just because it’ll shoot a half minute from a Tikka in the indoor target range (which it will) won’t change things like changing wind, how well you can read that wind, what the condition of your muzzle crown is like, or whether you have a tendency to drag the trigger left or right.

If you are a top-tier competitor like Kelly or Glenn, Eagle Eye lets you shoot your best without having to spend the time handloading. If you’re still building those skills, it means that you can learn that much faster, because you don’t have to wonder if a pulled shot was you or the ammo (it was you). You can learn to accurately call your shots that much more quickly. If you supply an agency that can’t handload for liability reasons, it means you can get handload quality from a factory produced product.

If you’ve done any serious load development for a precision rifle, you will know that different rifle don’t necessarily shoot best with the same loads. Some like a little more (or less) velocity or a slightly different bullet design than others. Eagle Eye doesn’t change that either, but it’s an excellent starting point. In fact, one of the elements that Eagle Eye kept in mind when designing their cartridges was trying to have them perform well in as wide a range of chamber s and barrels as possible. That’s why their .223 offering is a 69gr bullet and not something heavier – 69gr will run well is a significantly wider range of twist rates and chamber profiles. Their proprietary .308 projectile has a bit more bearing surface than some of the super high-performance designs out there, which allows it to mbe much less finicky about things like exact seating depth. In other words, they have done everything possible to get you the best performance our of the box in your rifle.

There will always be a place for handloaders who want to experiment with the most minute details of pairing a rifle and cartridge together, but I believe that Eagle Eye is an excellent solution for the folks who are more interested in spending time at the range practicing than time in the shop loading. It is currently priced at $38/box for .308 and $32/box for .223, and can be ordered through your favorite dealer or direct from Eagle Eye.

Your Privacy Choices

Your Privacy Choices