Prior to now, 3-D weapons were unpractical since they had significant risk at exploding with their contained ammunition. Simply put, the plastics available to common 3-D printers was not strong enough. While some could handle a few or even multiple rounds, many fired a single shot and disintegrated.

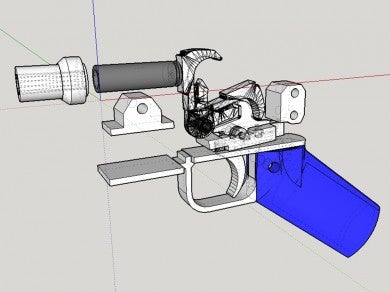

That has now changed with the introduction of the .314 Atlas by a 25-year-old machinist. In short, the .314 atlas is a reusable cartridge that is designed to contain the gunpowder explosion without the need of a reinforced chamber. This allows the .314 to be used in “very low end 3-D printers.”

WIRED has an excellent short expose into the machinist and his creation (which was fully BATFE legal). The inventor plans on releasing the specification to the internet, not as a political statement, but as a response to a technical challenge.

Author’s Note: Photos are from WIRED’s article. You can click on any of them to be taken to the original story.

Your Privacy Choices

Your Privacy Choices