I first met the faces of Bond Arms at a media event in Florida and had a chance to fire some of their fantastic wares on the range. I destroyed some paper with a .45/.410 model and gave the .38/.357 a try as well, and I was very pleased by the shootability and quality of the pistols.

I also learned that Bond Arms is local to me (maybe an hour away from my house) and once they learned I was a native Texan they asked if I would be interested in a tour of their manufacturing facility. I accepted with great enthusiasm, as I was very curious to see what went into making these fantastic little shooters.

Amy Graves, whom I had met in Florida is Bond Arms’ PR and media personality. Let me emphasize personality because she is a fantastic person who you just cant help but enjoy being around. In addition to marketing, Amy also very actively seeks out causes and charities that Bond Arms can help, and help they do. Amy picked me up at my shop which is located between her town and the Bond Arms facility which is located in Granbury, Texas.

Upon arriving at the facility, you can’t help but notice their very unique door handles:

Instantly I was greeted by Gordon Bond, the owner of Bond Arms and we decided to get a nice photo:

I also had a photo snapped of myself and the lovely Bond Arms’ Girl, Amy Graves:

After the entry to the foyer I got to sit down with Gordon Bond in his office and pick his brain a bit. On his desk was a lineup of how one of their pistols is produced step by step:

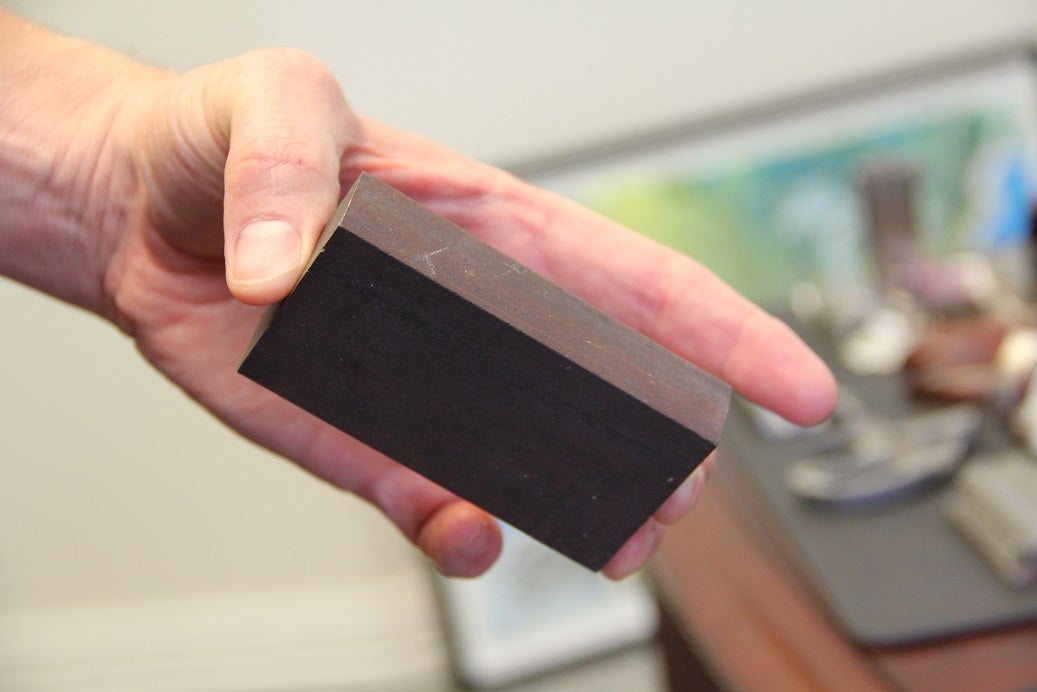

Every Bond Arms center-fire barrel starts out like this:

Talk about humble beginnings.

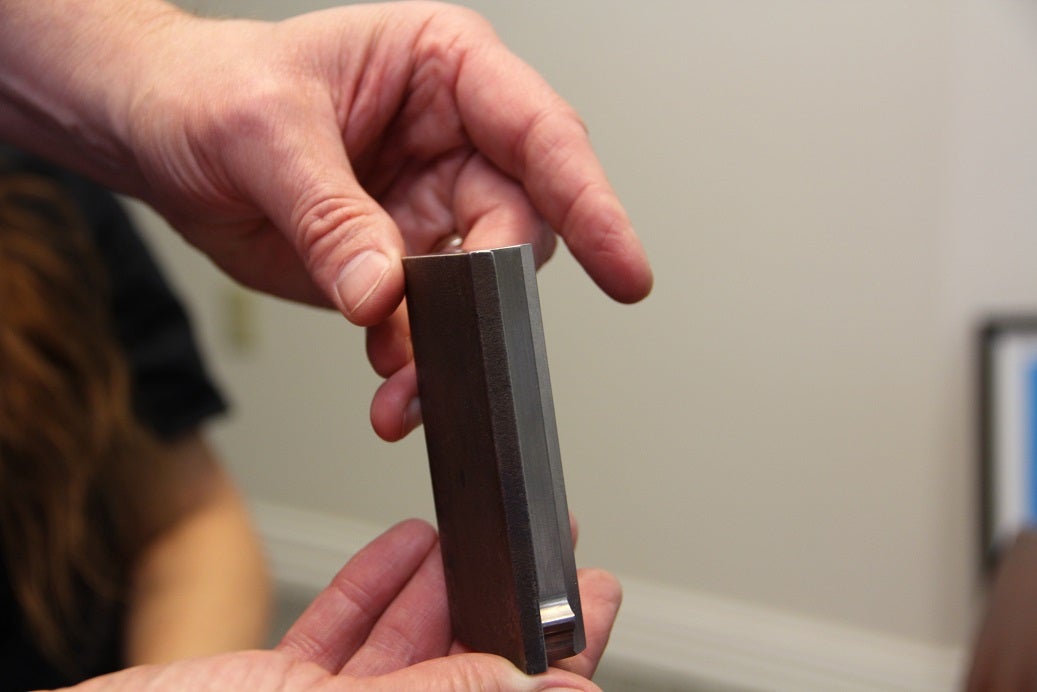

Machining starts and the barrel starts to take shape:

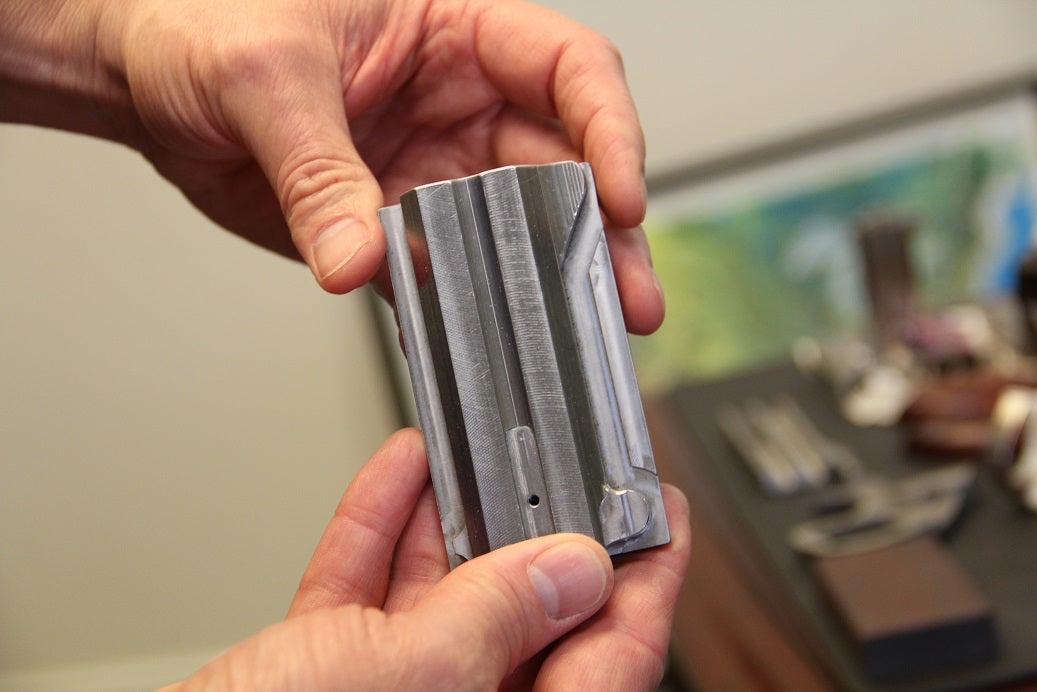

At one time barrels used to be cast, but now all barrels (including rimfire barrels) are machined. This is simply a relic of the old days:

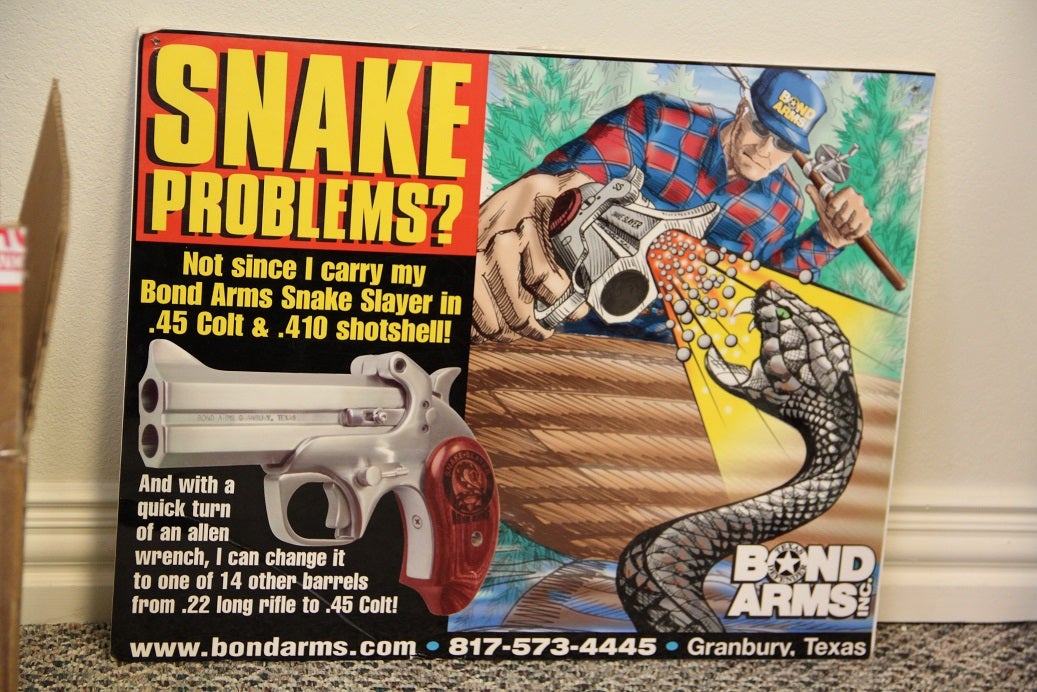

Also in the office was a great ad showing what I believe is a great use of the .45/.410 model: disposing of snakes and serpents that exist simply to make our lives more difficult:

Gordon also showed me his personal carry piece that he has engraved very tastefully that just looks fantastic:

This gun is of course fancier than the standard model, but even the bare bones guns look fantastic:

Anyways on with the tour. The first room I was lead through was the packaging and shipping department. This room is full of pistols ready to go out, as well as accessories:

Some loose pistols and barrels also peppered the room:

After the shipping department it was time to enter the manufacturing area that is secured (also, the sign is not that inviting!):

It all starts with the investment cast frames and machined barrels being turned over to the robots for basic polishing:

Robots start beautifying the parts:

I was allowed to take a video of this unique and cool process too:

The robots turn this:

Into this:

It is pretty neat to see what modern robotics can do, but there is still a human element to final polishing. A number of gentlemen work tediously to ensure that all Bond Arms pistols meet their standards (which are very, very high):

As I mentioned quality control, it is important to note the the things that get rejected at Bond Arms would be sent out by a lesser outfit. For example, this frame has an imperfection that is invisible to the naked eye (circled in black):

I am sworn to secrecy on how such things are rectified, but I can tell you it involves a very high precision, high cost machine:

After this, the repaired frame gets the existing mark polished out.

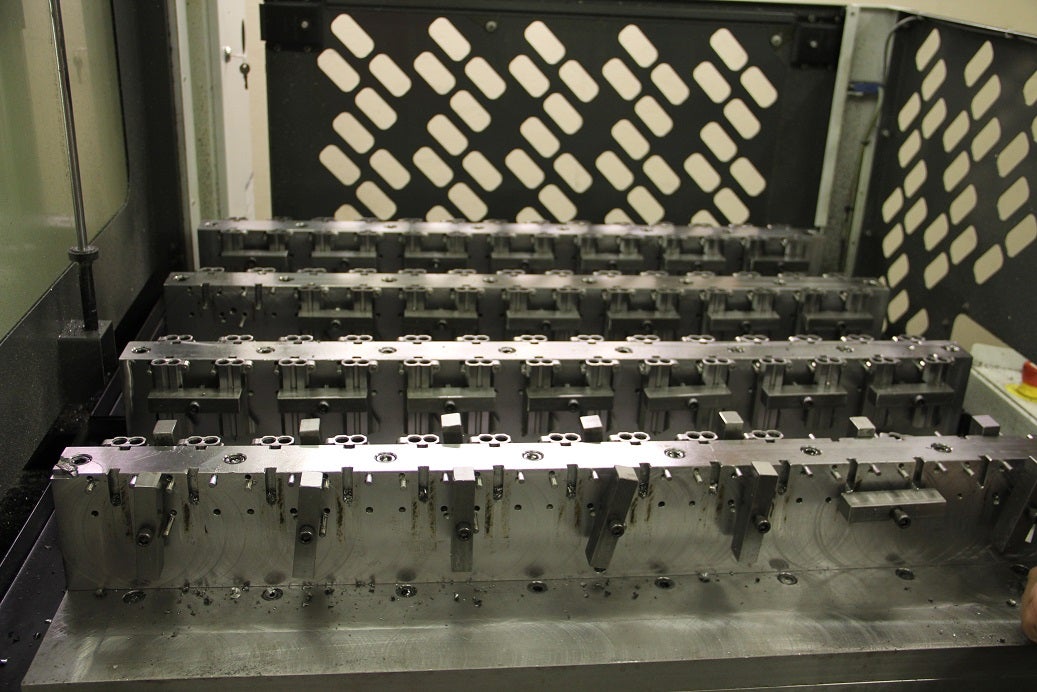

Rifling of the barrels occurs after machines cut initial holes. Barrels are first placed in a jig which allows them to be machined:

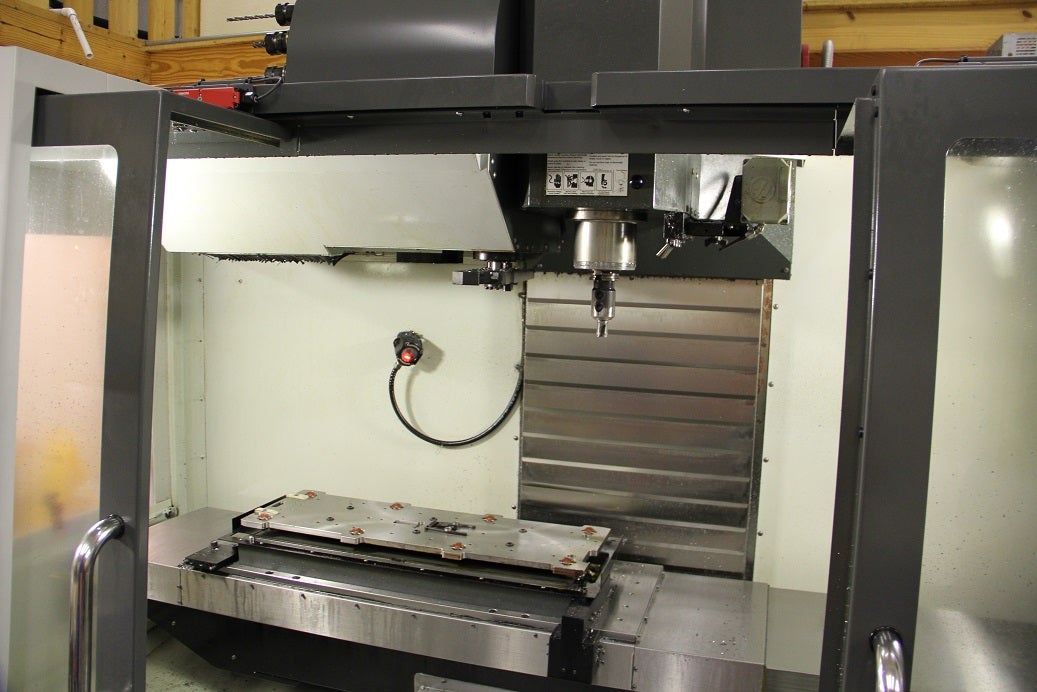

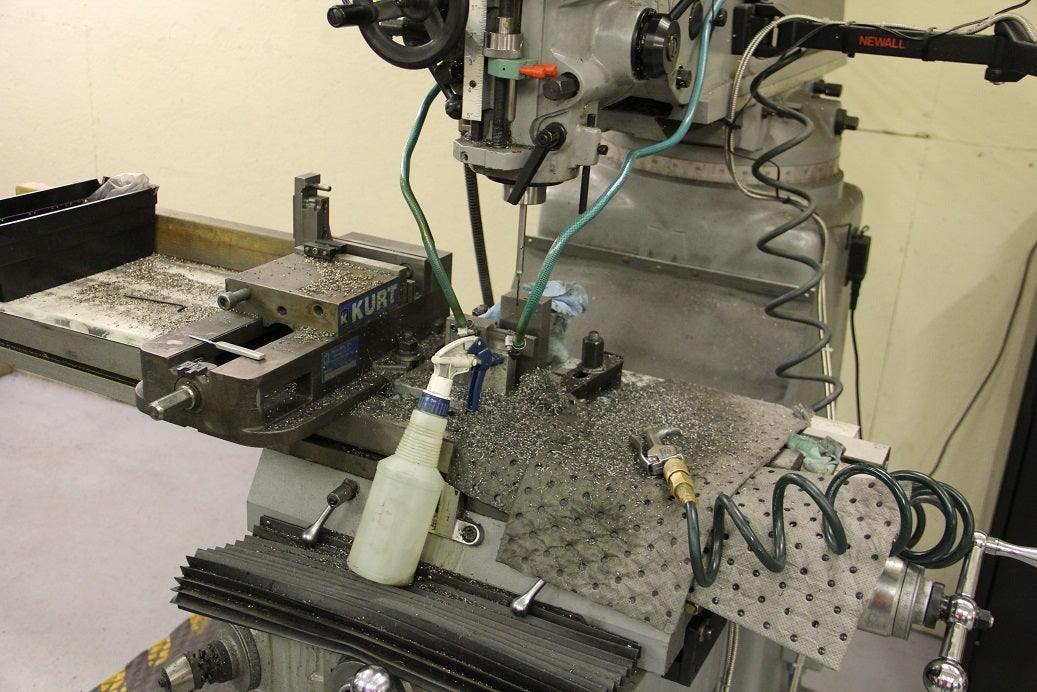

A lot goes on in the factory’s machine shop, which to me was overwhelmingly cool:

After this, barrels are rifled the old fashioned way: With a button!

The barrels are also crowned by hand:

Interestingly, at this point all rejected frames and other parts are destroyed by this press:

With barrels rifled and frames polished, it is time to assemble the guns.

Inside the shop is a small room full of small parts that are outsourced, such as screws, pins, etc. that would be cost and time prohibitive to make on site:

I also saw a pistol ready to be assembled:

Polished frames come to this station to be assembled:

the firing pins, lock-work, etc are added:

A small assembly line area has workers fitting parts to the guns:

Some guns get trigger guards, and some don’t depending on the gun’s model:

This machine marks frames/barrels with serial numbers and identifying data:

Mating barrels to frames is performed by a man on the end. He does what Gordon calls the “Bond Arms Flip,” which is when you unhinge the barrel and smack it in place with a flick of the wrist:

With final assembly, you now have a expertly made firearm that is sure to serve you for a lifetime:

Of course the guns being assembled doesn’t mean the process is finished. Some guns are accessorized with items such as the new grips for the California market (it is difficult making inroads to California to sell firearms due to bureaucratic processes, but Bond Arms has navigated them):

All products are test fired. This is a room purpose built for discharging a firearm. Barrels are put inside the port on the right:

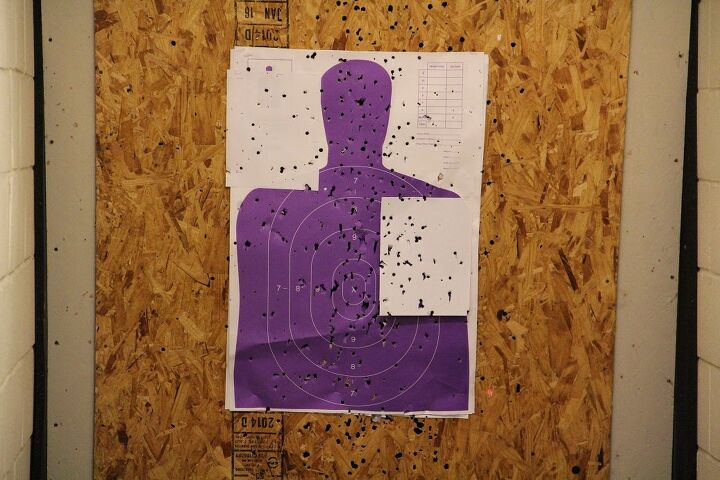

There is also a range for distance testing:

Of course with a Bond Arms .45/.410 you have plenty of options with which to dispense lead:

I was truly amazed at the workmanship that goes into these pieces. I never would have suspected how much goes into producing what I had previously regarded as simple and utilitarian firearms, but when you buy a Bond Arms product you can be sure that quality is an integral component. The men and women in the employ of the company work hard right here in my home state of Texas to make these fantastic firearms, and I was thoroughly impressed with the process and the pistols themselves.

A Bond Arms pistol might not be for you. It is easy to write off a derringer as an oddity or a cheaply made defensive firearm, but the crumby and cheaply made derringers of the past are not reflective of Bond Arms products. They fill a specific niches in the marketplace but demand is increasing, and I look forward to testing one to the fullest extent of my ability soon to post.

Also, this took place on October 30th of 2014. The next day I followed Bond Arms to capture the donation of a gun to a good cause. A living legend was present to receive it, and it was one of the most starstruck moments of my life. Sorry for the teaser, but stay tuned!

Your Privacy Choices

Your Privacy Choices