JerkingTheTrigger has created a step-by-step tutorial for shooters who are looking to move their Sig Sauer arm brace from one pistol receiver extension tube to another tube. The secret? Boil the brace. Tools needed? Minimal:

-

Stretched out SB15 Brace

-

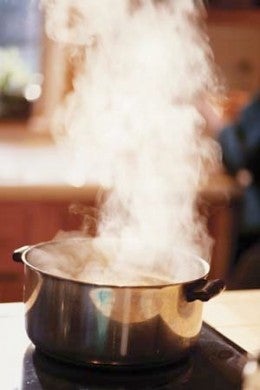

Soup/Stock Pot – Note: This pot needs to be big enough to hold the SB15 and enough water to cover it. Preferably, it should be large enough that it has room to hold all of that and little more so it doesn’t boil over.

-

Water

-

Stove

-

Timer

-

Kitchen tongs

As it turns out, the brace will contract when exposed to high temperatures and will reset itself back to its production diameter. For those looking for detailed directions (or just a good guffaw at their breaking-it-down-barney-style instructions) can hit the link to the original article.

Your Privacy Choices

Your Privacy Choices