Last July 2013 we announced the then brand new Sintercore Auxetik muzzle brake. After the announcement and short review I received several emails from readers telling me a 3D printed (laser sintering) muzzle brake would never hold up long term. There were also a number of comments about the price.

I considered those emails and comments a few days and decided on a long-term test. I really felt this new technology used to make muzzle brakes and other gun parts operating at high temps would have the ability to last a long time.

Of course I couldn’t afford to buy as much ammo as I wanted in order to do a short term test but if I used the Auxetik brake on every test I performed as well as during my regular weekly shooting I could get a good number of rounds run through it over a years period of time. That is exactly what I’ve done since July 16th last year until July 16th of this year.

Specifications

The first 3D printed muzzle brake available for commercial sale

World-class muzzle control on semi- and fully-automatic

100% Inconel superalloy construction, Ionbond DiamondBLACK coating

Threading: 1/2x28RH for 5.56 x 45mm / .223 and smaller

Included: Installation instructions, crush washer

Here is the number of rounds fired as well as under what circumstances. The total rounds fired in the year on semi-auto ran right at 7900.

At the end of the year I worked with a local shooter who put my upper on his registered lower. We gathered ten mags and loaded them with 62 grain green tip 5.56 rounds. We fired five magazines on full auto as fast we could fire and change mags. After the first five we allowed the rifle to cool for thirty minutes. We repeated the same process with five mags. This totaled 300 rounds fired full auto in a short time.

This concluded the shooting portion of the test. In the beginning I established a base view of the portions of the two interior chambers. This was done with a very small USB microscope. I performed another check at six months and finally a one-year check after the shooting portion was finished. Granted my instrument was pretty cheap but as far as I could determine there were no changes to the internal dimensions. I noted no signs of wear inside the two chambers or on the exterior vanes.

There was no discernable difference in performance over that year. There was no muzzle rise to speak of and no increase in report when firing.

My conclusion was the Sintercore muzzle brake held up extremely well to this long-term, high round count test.

In the last few weeks an interesting development happened at Sintercore. Neal, the owner of Sintercore, was contacted by the US Special Operation Command’s (USSOCOM) Science and Technology Directorate at MacDill Air Force Base. He was invited to demonstrate the newly named 3DX muzzle brake for possible use by these elite troops using an ARES Defense AMG-1 and AMG-2 belt fed machine gun with a 13 inch barrel feeding from a 200 round box magazine. On August the 5th 2014 testing was done by special operations troops on a closed range. All testing was done with the ARES AMG-1 and 2.

This is the official press release from Sintercore: Sintercore was invited to test its 3D printed metal muzzle brake with US Special Operation Command’s (USSOCOM) Science and Technology Directorate at MacDill Air Force Base on August 5, 2014. The testing was directly related to the development and testing of the Ares Defense AMG-1 and AMG-2 belt fed machine guns for potential acquisition by USSOCOM. Sintercore’s muzzle brake was compared to several competing products on the 13″ barreled Ares Defense machine guns, and testing included fully-automatic, sustained firing of up to 200 rounds per burst. The demonstration with USSOCOM operators yielded positive feedback regarding the 3D printed Sintercore muzzle brake. Sintercore will continue developing 3D printed firearms technology in order to exceed USSOCOM’s rigorous requirements and deliver world-class products to the civilian firearms market.

I can tell you the operators were very pleased with the results of the 3DX muzzle brake. Also Neal decided to change the name to the 3DX from the former name of the Auxetik muzzle brake. It seems people were really not sure how to pronounce it myself included!

On another note addressing the comments about cost. As I mentioned a year ago when a new product comes out the prices tend to be higher in order to recoup initial cost of development. I said then the price would drop which it has twice. The last decrease in price was $80.00 down to $223.56 with free shipping. This is right at half the initial price.

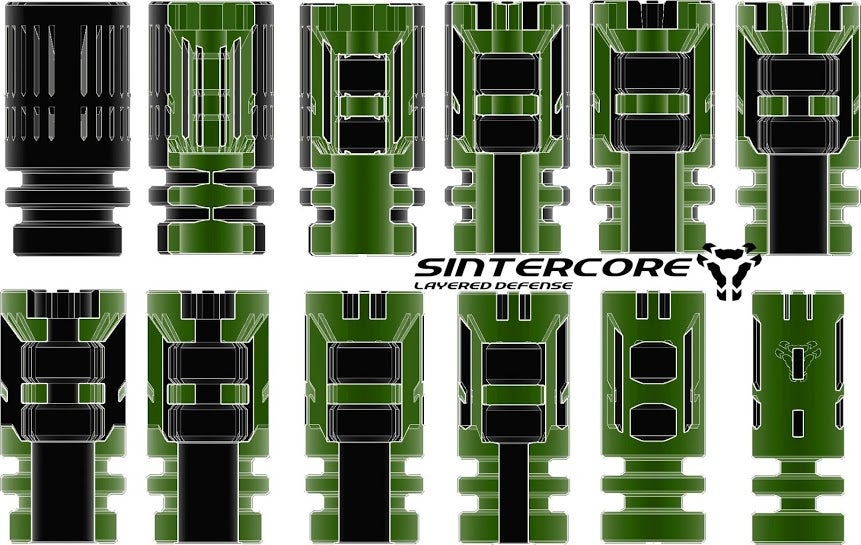

Sintercore has contracted with ION Bond to apply the Diamond Black coating to all future 3DX brakes. Current owners can also send in their silver colored brakes and have the new coating applied at no cost to the owner. Just contact Sintercore and arrange to send in your brake and it will be returned to you in the Black Diamond finish.

My personal conclusion is this is a very effective muzzle brake as you can see from the operator testing video. It also has the least flash as well as the least amount of noise of any comp I’ve used.It’s just my opinion but I think this is the best comp on the market. Now I just need one on my Tavor! One last thing I think the verdict is in a 3D printed muzzle brake will last a long time!

Your Privacy Choices

Your Privacy Choices