Hynek Vykoukal and Surujh Roopnarine took me on a tour of Meopta’s optics department. Unfortunately the first 7 mins of footage is corrupt so here are some pictures I took.

Here the worker is applying natural waxes as a bonding agent to hold the raw glass down while it’s machined into a prism.

Here is the CNC machine that cuts the glass into its initial shape.

They use Haas Milling machines to further form the glass.

This one is a 5 axis machine.

Tool heads for the 5 axis.

They also use a Satisloh PR-150 SL grinding machine.

Here are some optical elements mounted to either a glass or aluminum plate.

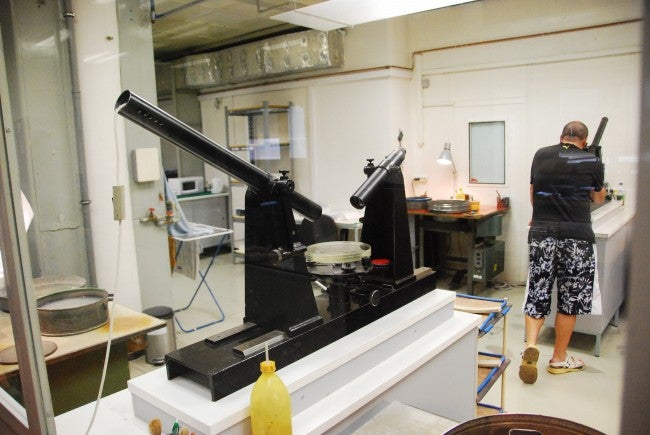

This grinding machine is rather old and yet is so efficient, it cuts down material in a fraction of the time other processes available do so they keep using it. Because of it’s high efficiency this stand alone machine does not create a bottleneck.

This team inspects the angles of the “wedges” aka prisms with these instruments. If the angle is not to spec, they can adjust the machines accordingly.

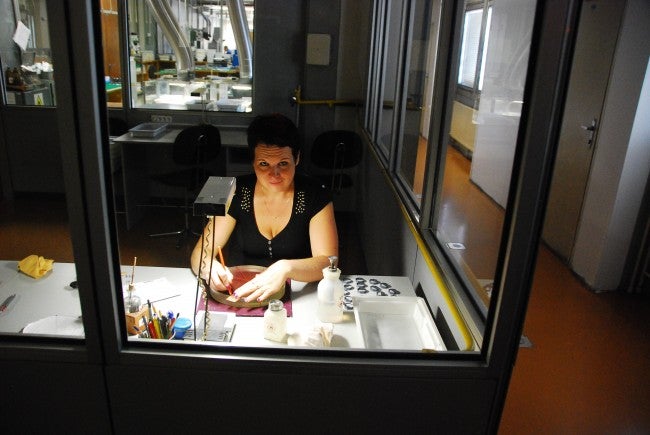

This lady is bonding elements to a glass plate without the use of any adhesive. According to Hynek, the two surfaces of the plate and element are so smooth that they adhere by molecular bonding.

These holders are made by Meopta to suspend the prisms in an Ultrasonic bath.

For some applications lenses and prisms need to be bonded together. They use UV curing adhesives.

For their 80th anniversary, Meopta created this sample case to showcase some of the elements they’ve made.

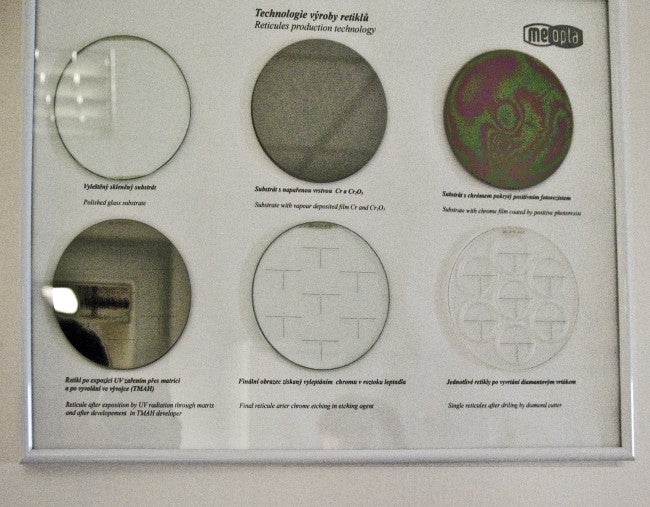

Here is a close up of reticle production. From left to right and top to bottom:

Substrate glass

Chromium coating layer

Photosensitive chemical

UV exposure photo etch

Removal of non etched material

Cutting the reticles out of the substrate

Here is where they expose the prepped glass for photo etching.

Here is a very cool machine used to analyze spherical lenses. It can measure the entire surface and does so by taking close detailed images and stitches the images together to make up a representation of the entire lens surface. It can measure all parts of the lens and determine if any part is out of spec. There is another machine tied to this that can spot grind/polish the lens back to specifications.

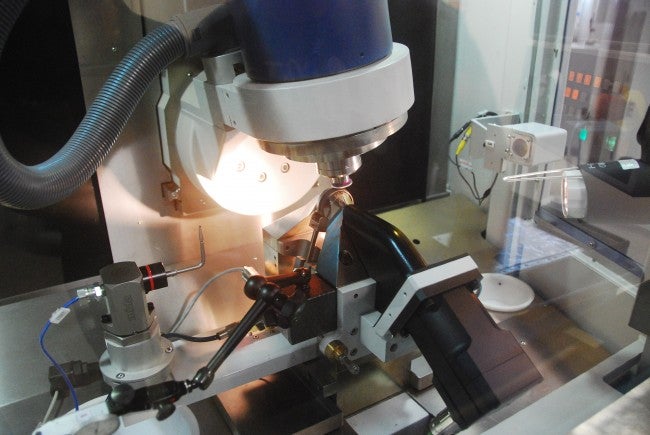

This is the machine that is tied to the ASI stitching machine. It uses a magnetic field to control a metallic liquid abrasive slurry and polish any specific spot on the lens. By controlling the magnetic field, the slurry can change shape and even hardness.

For smaller radius spherical lenses, Meopta uses these machines which are capable of covering such a radical change in angle.

Once the elements are polished they are sent to assembly. Stay tuned for the next installment which will focus on the assembly of their sporting optics.

Your Privacy Choices

Your Privacy Choices