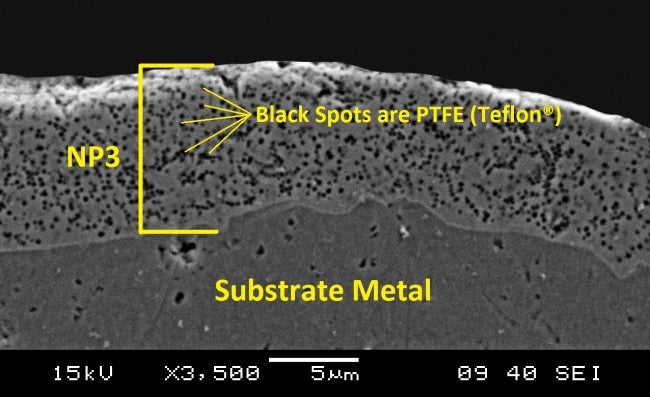

While I was down in Phoenix for the 3MR event, I learned that the trigger system had a coating on it called NP3. Also on hand for the media event was someone from ROBAR that was able to talk about the NP3 coating, and what it does. NP3 is a coating that is Electroless Nickle plating with PTFE (Teflon) in it. It is being used on firearm parts that are prone to wear, and has its own lubricity. After seeing triggers with several thousand round over them and they were barely even broken in, I wanted to know more about NP3.

NP3 has a lower coefficient of friction ranging from .07-.1, which provides even better performance than straight nickle boron coatings. As the NP3 breaks in, it begins to take on a polished look. The polishing is actually what is exposing the PTFE in the coating to provide lubrication. The finish doesn’t actually wear any further than the break in point, and it actually quite a tough coating. The NP3 coating is so resistant to wear, while also reducing corrosion that aerospace companies are also using it for aircraft parts. The corrosion resistance for the NP3+ is at 1000hrs of salt spray, which is done by the ASTM-B117 standards. The next closest coating is electroless nickel boron, which is right around 100hrs.

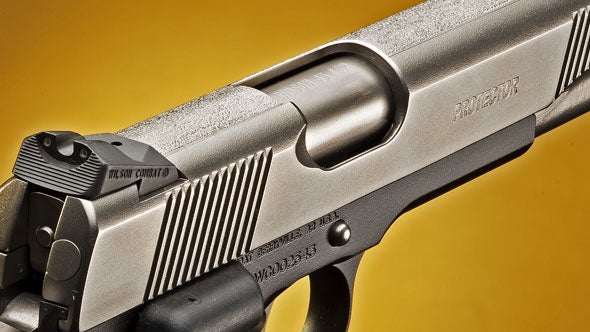

ROBAR is able to coat entire pistols, AR’s or just about anything else with the stuff and it also carries a lifetime warranty. While on the more expensive side of some of the coatings out there, guns that see hard use, every day carry or salt environments would benefit greatly from NP3 coating. NP3 also makes cleaning easy enough to just need a soft cloth to wipe everything down. After watching the ROBAR rep shoot 500rds on a completely dry upper and BCG, I was pretty impressed with the coating and what it can do for firearms.

If you want more info on NP3, or ROBAR you can visit their website: http://robarguns.com/

Your Privacy Choices

Your Privacy Choices