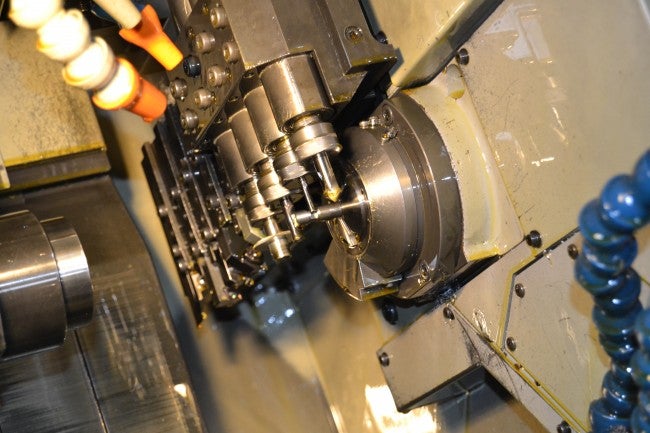

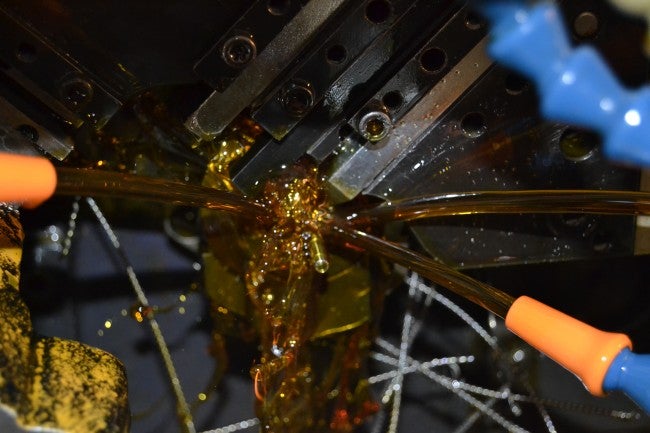

This morning we were all treated to a tour of one of the production facilities that TAC-CON uses to manufacture the components to make their trigger system. Being an aerospace facility, the product that is being made is of the highest quality, and tightest tolerances.

Also as part of the tour, we were each given a kit to assemble one of their triggers. Included was all the parts needed to make a fully functional trigger system. While at first a little daunting, assembly was actually easy. Once assembled, we were walked through a function check of the trigger system.

What was released to us was a new ambidextrous safety selector that they will begin shipping with all triggers in the near future, with those that purchased triggers with a single sided safety the option to buy an ambi-safety from them.

After the afternoon break we are headed to the range for hands on shooting with the trigger to get a better feel for how it is designed to function, what the functions are for and to get better at shooting with the trigger.

One part to the discussion this morning was the concept and thought process behind the trigger. It was designed as a way to give people in a high stress setting a reset on the trigger and not get into the “death-grip” scenario, where they only fire one round. The trigger is an auto-reset in the third position, forcing the user to reset the trigger for another shot. The ability to rapidly fire the system was actually a side benefit to the way the reset system works, according the TAC-CON President Mike Stakes. This was actually to me, sheds a new light on the company and what they were looking to create for the firearms community and, at least to me, shed light on the reason they are being marketed to law enforcement as well.

This evening at the range should prove to be an exciting look into the function of the trigger system, how it works and getting used to using it. Look for more this evening!

Your Privacy Choices

Your Privacy Choices