ATI has been competing with a number of other companies to create a true polymer lower for over a year now. ATI had created the first OMNI polymer lower, which was reviewed here at TheFirearmBlog in February of 2013. While the reviewer here had no problems with the lower, there are many cases described online of those lowers failing at the buffer tube collar and rear take down pin. In response ATI created a second generation of the OMNI Lower, which has an aluminum block around the buffer tube collar and rear take down pin. While these changes appear to solve those earlier problems with polymer lowers, the new Gen2 Omni Hybrid rifles I received exhibited more serious problems.

My initial impression of the lower was that it is very light. With a stock flat top upper the complete rifle weighed in right at 4.5lbs. With a loaded steel 30rd magazine it weighs 6lbs. That weight is pretty impressive for a complete rifle with a loaded magazine. That is where the impressive attributes for this rifle ended. The first problem I had was the rear takedown pin. In order to push the takedown pin through you either need a punch or a 5.56 cartridge. This is not like a standard aluminum lower, where the take down pins protrude enough to push them out with your fingers, giving the shooter the ability to remove the upper in the field without any tools. While you are more than likely going to have a 5.56 cartridge while out shooting, it is still an annoyance to me to have to strip a round in order to access the internal workings of the lower.

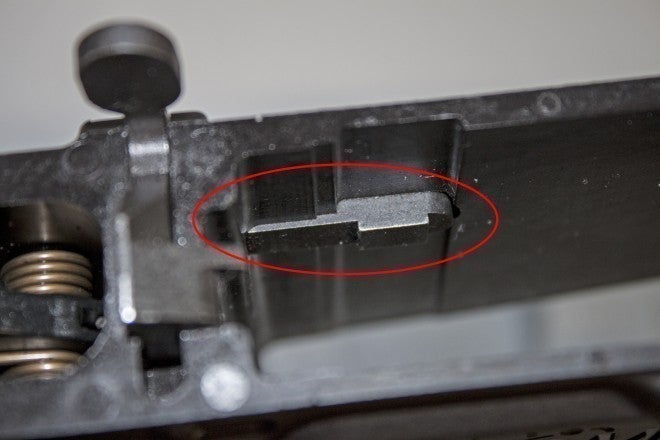

The second issue, and even more of an annoyance than the first, is that ATI built their own anti-walk system on this lower. There is built up polymer above the trigger pins that are threaded and contains a

small slotted flush screw. In the event of a fire control group (FCG) failure, you would need a small slotted screwdriver in order to remove the pins. While generally removing the FCG is not a function of field stripping, the beauty of the AR design is that it can be done quickly with nothing more than a punch. This lower requires the user to carry more tools into the field if they anticipate having to do FCG repairs. Personally, I have never been an advocate for anti-walk devices on the AR platform in the first place. Anti-walk system are available to those that choose to install them if there is a want or need to do so. But there is a difference between installing your own, and being forced into an anti-walk system that is part of the lower. Having fired my fair share of 5.56mm / .223 Rem. rounds from AR-15s and military M16s and M4s I have never once a problem with a FCG pin walking out and rendering the FCG inoperable. While the inclusion of them might have to do with the polymer lower, they were not included on the first generation of ATI polymer lowers.

Shooting this rifle was a different feel from the standard AR15. Something about the polymer, low weight and slow cycle speed combined to make the entire bolt carrier group (BCG) stroke very noticeable to the user. During every shot down range, I was acutely aware of the BCG travelling rearward, then stripping a round and finally closing. I was able to fire a total of three 30rd magazines of Federal XM193 55gr rounds before failures started. After inserting a fresh Magpul Gen2 P-Mag and firing three round, the magazine spontaneously ejected from the rifle without the magazine release being pushed. I collected the brass that had just come out of the rifle to inspect it for a pushed primer, pressure signs or an out of battery detonation. I found the brass to be normal and uniform with all of the spent brass I had fired to this point. I inspected the rifle for any signs of a problem or cracking in the lower and found none. I then inserted the same magazine into the rifle, dropped the bolt which chambered a round and fired the round by pulling the trigger. After firing the round, the next round in the magazine was a failure to feed (FTF), binding about halfway into the chamber. I was able to clear the FTF, chamber a new round and then got a failure to eject (FTE) the spent casing. I was able to manually cycle the action with the charging handle, chamber a new round and then fire the rifle again. The rest of the magazine were all FTFs and FTEs. I was able to look into the ejection port, and found that all of the FTF were

Out of tolerance magwell and magazine wobble caused the follower to miss the bolt catch on several occasions.

being caused by the round nosing down into the area below the feed ramps and binding the action of the rifle when the bolt was headed forward. I took the magazine out of the rifle, inserted an empty magazine and took notice of just how much that the magazine was able to move in the magwell. At this time I also discovered that I was able to tweak the magazine, and remove it from the rifle without using the magazine release. I did this several times, and even gave the rifle to a shooting partner who was also able to replicate the problem himself. I was able to replicate this with a steel GI magazine, and also Gen1 and Gen2 P-Mags. The last problem that the rifle was exhibiting was the bolt not locking back on the last fired round. I was able to remove the upper, and see that the magwell was loose enough to cause the magazine follower to miss the bolt catch, and allow it to ride behind the follower, failing to lock the bolt back. At this point I felt that the rifle no longer safe to continue shooting because of the problems I encountered, including magazine that fell out spontaneously, and the ability to remove the magazine without using the magazine release.

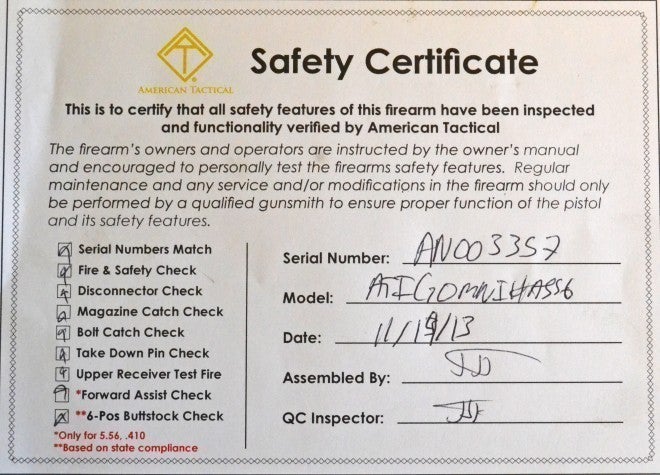

ATI was given the chance to send out another rifle for testing, in the event that the failures of the previous rifle were an isolated problem. The serial number of the first rifle was AN000835, which would lead me to believe that this lower was #835 off the line. The new rifle that was received was AN003357, which happens to be 2,522 down the line if the serial is an indication of the order of manufacture. The first impression of the new rifle was problematic, just out of the box at my local FFL was the charging handle bound inside the upper about halfway back. This happened when picking up the rifle for the first time and checking to ensure the rifle was not loaded prior to handling it. I was unable to get the charging handle to go either back into place or continue all the way to the rear. My FFL, who also is a 07 manufacturer, had to get a hammer to get the charging handle free. After replicating the problem, he made the remark “This rifle is probably unsafe, and if you were just a regular customer, I would not let it out of my shop. It would be going straight back to the manufacturer for a replacement or to be fixed.”

Knowing at that point I would not be shooting the new rifle. Having a charging handle that binds in the upper could cause a catastrophic failure if it were to get free during shooting. I took the complete rifle back to my bench and decided to try the charging handle in an upper I know is within spec, the handle did not move, or bind at all. I took a Rainier Arms Raptor handle, which I know is a high quality handle, and within spec, and put it in the ATI upper on the new rifle, and got the same binding problem. This led me to believe that the charging handle slot in the upper was not milled properly, and was unsafe to shoot.

Both rifles were taken to a highly regarded gunsmith in the local area for evaluation. He took both rifles apart and found the measurements on both to be out of spec in several places, including the magwell and the magazine release. We found that the magwell in both rifles was too large. Specifically it was

.003” too large both in length and width, leading to the magazine wobble that I experienced with both rifles. The wobble, coupled with the flex in the polymer lower, caused the magazine to come free without using the magazine release on both rifles (#835 and #3357). The charging handle slots in rifle #3357 are .002” too wide, and the rails that retain the charging handle in the slot were almost nonexistent. This meant that the charging handle was able to bind inside the upper when the tabs bound on the out of spec retention rails. He also found that the upper that was sent with rifle #3357 was fired, in his opinion, much more than the three factory rounds. There was significant wear in the chamber and a large quantity of unburned powder in the chamber and bolt lugs. Having not fired rifle #3357 myself, this was directly from the manufacturer in this condition. The upper shows a build date of Nov 17th 2013, and shows 3 empty casings in the box with the rifle. In his professional opinion both rifles were unsafe to shoot, and would not leave his shop if someone was to order them. His final report to me was that both of these rifles were out of tolerance, and would eventually lead to someone getting hurt.

There were also several other small things that I noticed about the original rifle that was sent. The first was that the polymer flow at the buffer tube collar and aluminum block was incomplete. This would lead me to believe that there was either a flaw in the mold used, or the polymer mixture itself. Being that it is within the first 1000 produced, it is entirely possible that there were problems with the molding process, be it the heat used, polymer blend or the mold used. While this particular issue does not look like it will be causing any structural issues, it is something to note that they were having what looks to be some flow issues. In the new lower #3357, the flow issue looks to be resolved, and look to be within normal limits. What stuck out in my mind was that if there were flow problems with lower #835, where else might there not be enough polymer material in a more critical place that is out of sight that might have caused a failure down the road.

One final note is that rifle #3357 came with was a safety certificate. The certificate also suggests that any regular maintenance, which would include cleaning, be done by a qualified gunsmith, or the safety of the rifle cannot be guaranteed. While I will occasionally I will take a firearm to a gunsmith for a deep clean and inspection, I would never take a firearm in for routine cleaning. This certificate would suggest that ATI is implying that if you cleaning the rifle, what can be considered as routine maintenance, and there was a failure or safety problem that it would be the fault of the owner and not ATI. This appears to be a thinly veiled attempt to shift the blame for any problems with a poorly made, out of spec rifle onto the owner simply for doing what millions of gun owners do every day.

Conclusion

My conclusion of both of these ATI rifles is that they are unsafe. I have shot a lot of AR-15s in my life, including military M16s and M4s during my time in the Coast Guard. I have never felt unsafe shooting a semi-automatic rifle, no matter who the manufacturer was. I own two rifles that some consider mid-grade in terms of quality, and have never felt that they are unsafe. They might not be as tight tolerance wise or as accurate as a high end AR, but at the end of the day, they do not make me feel unsafe like these rifles did. Personally, I would not buy an ATI OMNI Gen2 lower or complete rifle, I would not own one and I sure would not hand one of them to a loved one to shoot. If one of these rifles was to have a out of battery detonation, or catastrophic failure the polymer would blow apart into small pieces, embedding itself into your arm, body, legs and face. While aluminum can fail as well, it has been engineered to fail at certain places directing the blast and fragments away from the user. This is why we have seen catastrophic failures, only to learn that the shooter walked away with nothing more than a small cut.

They have fixed the problem of the polymer failing around the rear take down pin and the buffer tube collar, but there are just too many other problems with them right now to be able to recommend that you run out and buy a polymer lower. If you happen to want to build a nice, light rifle my suggestions would be to find a good aluminum lower, and build the rifle with light materials. While some will call this a step in the right direction for polymer, it is still far from ready for the open market. These rifles, as received from ATI are, in my opinion, coupled with the opinion of two gunsmiths, unsafe. They are out of tolerance and can and will hurt someone that shoots them if ATI continue to sell them as built. Save a few more dollars and get something better and more reliable made out of aluminum. Remember, you are purposely setting off an explosion that is 3” from your face; safety is paramount and should never be compromised to save a few bucks.

- Out of spec magewell. This magwell is .003″ too wide and long, making the magazine unstable.

Left side of lower receiver, clearly shows the anti-walk system created by ATI as well as the serial number plate and company name above the magwell..

Circle shows magazine release protruding beyond the magwell behind the magazine catch, the left side of the magazine catch should be flush to the lower.

Out of tolerance magwell and magazine wobble caused the follower to miss the bolt catch on several occasions while shooting.

Out of tolerance magwell and magazine wobble caused the follower to miss the bolt catch on several occasions while shooting.

Steve (The Editor) writes: Two days ago, after I had edited the final copy of this review, I sent a copy to ATI and asked them if they would like to send us a response which I would post below. the article. As I always do, I made it clear that I would not alter the review in anyway. I did, however, agree with their comment (in the third paragraph below) that the two photos I had included of a cracked lower from another company (for comparison purposes) is confusing and I decided to removed them. Nothing else has been added or removed. Their response …

December 19, 2013

To the Firearm Blog, Thank you for offering us an opportunity to read and respond to this review prior to publication.

While we at American Tactical greatly appreciate the information presented in this review, we are unable to agree with or verify the issues stated by Mr. Cadle, as we have not received either of these firearms back for our own service department to review. The return process for the firearms sent to Mr. Cadle is now underway. Once received, our full‐time gunsmiths will check each gun against the information provided in this review, so that we may address any issues, should they be present.

We would also like to make it very clear that the images used in this review that depict a cracked buffer tube collar are NOT images of the Omni Hybrid lower receiver.

American Tactical also does not know the circumstances of the firearms in between the time they left our facility and were picked up by Mr. Cadle. We do not know if the firearms for this review were inappropriately handled prior to his arrival at his FFL to receive them. We only test fire three rounds through each final assembly for functionality prior to full cleaning and packaging of our products. For liability reasons these test firings are performed by teams of staff and recorded should we experience any issues. We are unable to explain the claim of more than three rounds fired and an unclean rifle prior to Mr. Cadle’s first inspection of the second rifle we sent him.

Polymer molded AR lowers are still a relatively new item in the Shooting Sports industry, and the American Tactical Omni Hybrid is the newest innovation in design for this developing market. We understand that new technologies, especially those that challenge conventional thoughts and perceptions can often be met with resistance. American Tactical has chosen to embrace this new technology and is fully confident in it; so much so, that all Omni Hybrid lower receivers come with our first ever offered Lifetime Warranty in addition to the standard 2 year warranty that accompanies our rifles.

Thank you,

Management

American Tactical

Your Privacy Choices

Your Privacy Choices