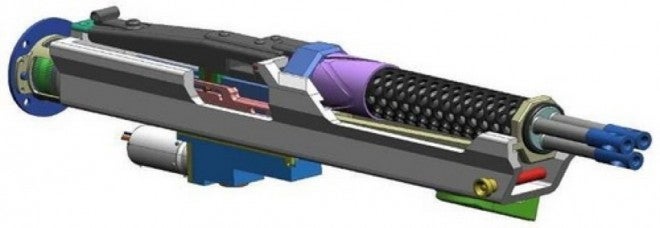

Rheinmetall Defence are developing a new 7.62mm medium machine gun called the RMG 7.62 which takes a unique approach to dealing with heat, the age-old machine gun nemesis. At first glance it looks like a small version of the M134 Minigun, but the RMG is no Minigun. Unlike the Minigun, with its insane rate of fire, the RMG is designed to fire at the relatively slow pace of 800 rounds per minute (the exact rate of fire is user adjustable). What it lacks in speed it makes up for in endurance. When its barrel gets over heated the electronics rotate the barrels, replacing the hot barrel for a cool one.

The three barrel system would obviously be unpractical for soldiers on the ground, but it is perfect for use with remotely controlled gun mounts where it is neither possible nor safe for the operator to swap barrels manually. This setup would allow the remote-controlled gun to fire a lot more rounds and take fewer breaks than would be possible with a conventional single-barrel machine gun like the MG3.

The short clip shows a prototype RMG 762 firing but does not show the barrel changing procedure …

Many thanks to Kirill for the tip.

Your Privacy Choices

Your Privacy Choices