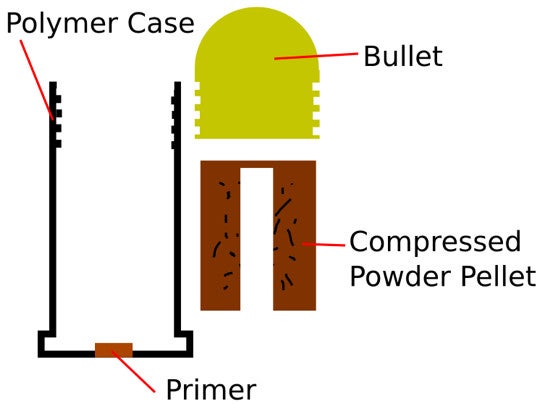

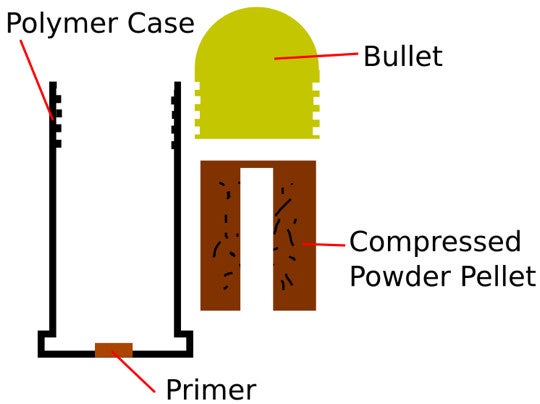

Last night I had a dream where I was at the range (many of my dreams start at the range). A friend asked me if a 9mm Luger load with a heavier bullet would shoot more accuracy. I turned around, unziped my range bag and took out pre-primed cases, bullets of the correct weight and a box of compressed powder pellets. I put the powder pellet into the case, screwed in the bullet and then handed the loaded cartridge to my friend.

The concept my unconscious brain come up hinges on having a polymer case with internal screw threads that will break off when the round is fired. The hard copper threads of the bullet should cleanly strip the polymer case threads.

I like the idea of being able to create a custom load on demand is nifty, but this idea is fraught with numerous problems. The bullet seat depth could not be controlled, the cases would need to be pre-primed, compressed powder does not burn as well as uncompressed powder (and powders would need to be developed), bullets would be more expensive and accuracy would not be as good as a conventional loaded round. Don’t expect Steve’s Special Supreme Modular Polymer Rounds to appear on the shelf of your local ammo retailer anytime soon.

Your Privacy Choices

Your Privacy Choices