The Revised Edition of The Modern American Pistols and Revolvers by A. C. Gould was published in 1896. It contains a thorough a description of the state of the art of pistol shooting before the turn of the century. I have uploaded the PDF to Scribd where it can be read and downloaded.

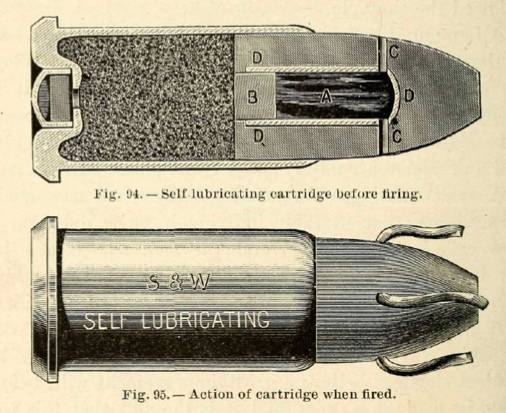

On Page 140 the author discusses Smith & Wesson’s self lubricating bullets. A copper tube containing lubricant was inside the lead bullet. Behind the tube was a brass stopper. When the cartridge was fired, the stopper was pushed through the copper tube forcing the lubricant through four holes in the bullet. The lubricant supposedly reduced fouling and increased accuracy. A. C. Gould wrote …

Viewing this cartridge solely on the grounds of accuracy, it is in every way a superior cartridge. The radical departure in its construction caused me to watch vigilantly for irregularities in shooting, but I discovered none. There was not a keyhole in several hundred shots fired, not an unaccountable; and while I am not prepared to say that it was the most accurate cartridge known, I do not hesitate to state that I have never seen any more accurate central-fire cartridges when fired from a revolver.

I think modern target shooters would be horrified by the thought of a bullet containing moving parts and changing shape and weight inside the barrel!

[ Many thanks to Sven (Defense and Freedom) for emailing me the book. ]

Your Privacy Choices

Your Privacy Choices