MIL-STD 1913 aka. the Picatinny rail attachment system, is will eventually be replaced by STANAG 4694, otherwise known as the NATO Accessory Rail (NAR). On May 8 the powers-that-be at the NATO Standardisation Agency approved the new standard, which will now need to be ratified by individual NATO member countries.

Don’t get worried about your countless picatinny compatible attachments being obsolete, the system is fully compatible with picatinny compatible accessories. According to DTIC.mil (PDF link) the differences between the MIL-STD 1913 and the NAR are:

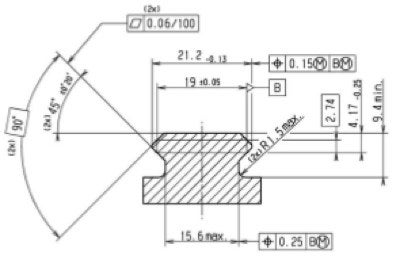

* Metric reference drawing (see below).

* Additional measurements and tolerances.

* Adjustments of some measurements.

* Reduction of straightness tolerances (presumably making the manufacture cheaper).

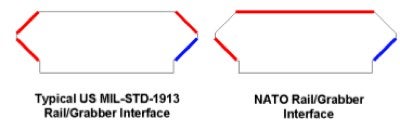

Another notable change is the recommendation that while in the picatinny system the V-angles are used for the alignment and reference of the accessory, such as detachable optics, NATO recommends using the top surface instead. They say that tests have shown that this increases repeatable alignment.

Recommended surfaces to use for alignment.

According to Janes many countries contributes to the new standard, including many of the top military arms manufacturers:

Designed in conjunction with a number of weapon specialists including Aimpoint, Beretta, Colt Canada, FN Herstal and Heckler & Koch, the NAR system has full compatibility with current US MIL-STD-1913 specifications, also known as the Picatinny rail.

It will be interesting to see how long it takes before civilian arms claim “STANAG compatible rails”.

A big thank you to jesse for emailing me about the new system.

UPDATE: Mark posted a link to another DTIC.mil (PDF warning) presentation that discusses the future developments of the NAR.

NATO members are currently working on working on a powered rail design that extends STANAG 4694. The idea is to have a single battery to power all the accessories and optics of the firearm.

Battery in the pistol grip, power management in fore grip

I have blogged about powered picatinny rails before.

Your Privacy Choices

Your Privacy Choices